BASF SE

Carl-Bosch-Strasse 38

Ludwigshafen, D-67056 DE

49 900621 60 0

basf.com

About BASF SE

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

BASF SE Supplies the Following Products

- Nylon (polyamide)

- Polyurethane (PU)

Editorial, News, and Products

-

AIM3D evaluates potential of composite extrusion modeling 3D printing test with PA6GF30

Glass fiber-reinforced polyamide 3D-printed test specimens proved higher tensile strength, cost effectiveness compared to injection molding and conventional 3D printing processes.

-

ALMACO discloses Top of Mind 2021 award finalists

The primary award for the Brazilian composites sector identifies the three most-voted companies in 27 categories. Winners will be announced Dec. 9.

-

Riding pretty: Hybrid upper control arms move to pickups

Short-glass/PA6 with metallic inserts reduces mass, running torque, joint wear on the Ram 1500 half-ton pickup truck.

-

Composites feature in Altair’s 8th Annual Enlighten Awards

Recognized jointly with the Center for Automotive Research (CAR), winners represent the world’s best initiatives to reduce vehicle weight and meet emissions targets.

-

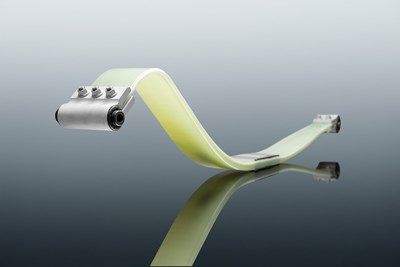

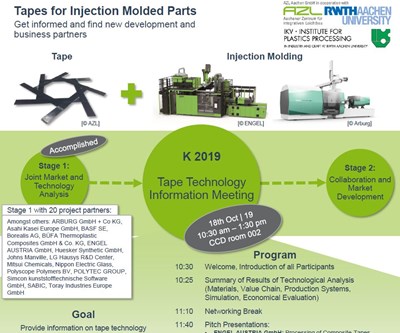

Research project reports potential for tape inserts in injection molding

The research consortium, led by the Aachen Center for Integrative Lightweight Production and the Institute for Plastics Processing at RWTH Aachen University, will present its results at K 2019.

-

BASF to build engineering plastics, thermoplastic polyurethanes plants in China

The two plants will be located at the company’s proposed integrated chemical production site in Zhanjiang, China.

-

Measuring and improving fire resistance in composites

Sidebar to CW’s Feb 2019 feature article, this quick review of fire tests for composites also provides more details about intriguing new material developments.

-

Withstanding fire without the weight

New composites meet stringent fire requirements while lightweighting ships, rail cars and battery boxes for electric cars and planes.

-

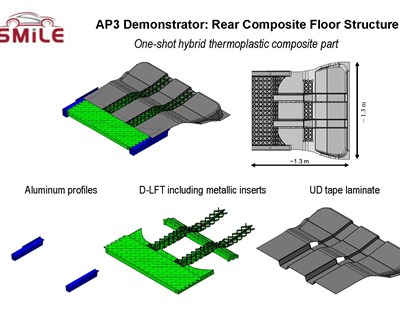

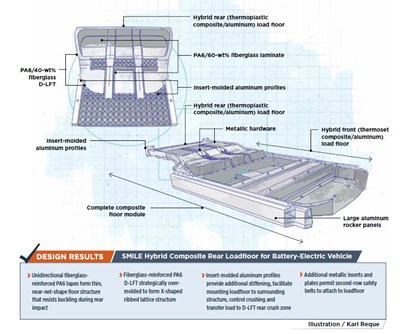

Continuous tapes, D-LFT meet up in new compression molding process

Design research for an automotive load floor module drove development of a new compression molding process for direct-long-fiber thermoplastic (D-LFT) composites.

-

Hybrid thermoplastics give load floor impact strength

Project leads to development of new compression process for selective application of D-LFT on UD tape laminates.

-

AVK announces winners of 2017 Innovation Awards

AVK Industrievereinigung Verstärkte Kunststoffe e.V. (Frankfurt, Germany) has announced the winners of its three prestigious Innovation Awards to institutions, companies and their partners in the composites industry.

-

IAC debuts FiberFrame on 2017 Mercedes-Benz

Germany-based International Automotive Components (IAC) has launched its ultra lightweight FiberFrame natural fiber sun roof frame on the 2017 Mercedes-Benz E-Class.

-

Composites extend service of oil and gas pipelines

Corrosion-resistant aramid fiber/thermoplastic liner gives new life to deteriorating steel subsea pipelines.

-

The rise of HP-RTM

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

-

Polyamide improves impeller performance

Direct-to-milled-tool process simplifies large deck mold development.

-

Autocomposites Update: Engine oil pans

As thermoplastic composites makes inroads into these complex, modular parts, weight and cost go down, functionality goes up.

-

JEC Europe 2013 review

Snow in Paris slowed traffic to the show floor but did nothing to cool the enthusiasm of composites innovators in a broad range of markets.

-

SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

-

Chevy Volt battery pack: Rugged but precise

GM and partners engineer composites for this complex assembly with an accent on repeatability.

-

High-temp thermoplastics: Higher Expectations

As the drive to greater fuel efficiency under the hood catches fire, fiber-reinforced thermoplastics prove they can take the heat.

-

Under the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

-

Interior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

-

CNTs ride a rising tide of nanotech optimism

Dr. Louis Pilato offers facts, figures and comment on the growing utility of carbon nanotechnologies in composites applications.

-

SPE's ACCE 2009 Show Preview

The Society’s 2009 Automotive Composites Conference & Exhibition charts an industry at a crossroads.