Compression Molding

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

WatchActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

WatchGuidance for the thermoforming process

A briefing on some of the common foam core material types, forming methods and tooling requirements.

Read MoreHydraulic, transfer press lines provide precision composite molding

CAMX 2024: Wabash MPI/Carver Inc. highlight the Genesis Series of hydraulic presses, as well as a line of transfer presses, engineered for compression molding of various materials.

Read MoreSicomin, Fairmat to create recycled CFRP stiffener for body scale

French specialists work together to match epoxy resin production and compatibility targets for a next-gen digital body scan scale product.

Read MoreHybrid composite workcell supports thermosets, thermoplastics

CAMX 2024: Radius Engineering showcases its Hybrid Composite Workcell with the versatility to support a range of closed-mold processes monitored by its Insights control system.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreHyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

Read MoreInduction heating platen achieves dynamic temperature management

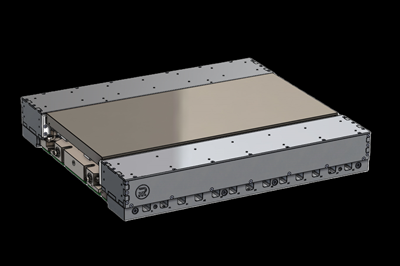

JEC World 2024: Roctool is introducing the R-IDS, a patented heated platen that aims to make mass production more accessible for composites manufacturing.

Read More