Compression Molding

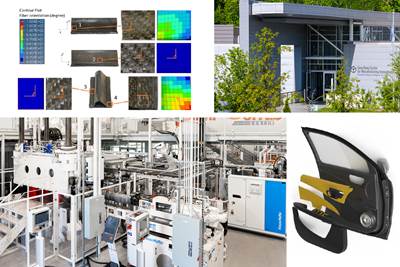

Clemson Composites Center: Working with industry to transform composites

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

Read MoreSolvay expands Solvalite portfolio into automotive, invest in Xencor LFT production facilities

New fast curing carbon fiber and woven fabric prepregs target high-volume automotive applications such as body panels with optimized structural part performance.

Read MoreHypetex creates colored carbon fiber covers for IQOS tobacco heating devices

The U.K. manufacturer and supplier of advanced materials coordinated all aspects, from initial concept to final solution, including a fully optimized production process.

Read MoreLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

Read MoreLanxess expands Tepex flowcore composite range

Focusing on lightweight components for cars, sports equipment and consumer goods, the long fiber-reinforced thermoplastic enhances ductility, recylability and processability.

Read MoreCFRP breakdown poles designed for lightweight, long-lasting use in marine applications

Shellback Canvas LLC wanted to develop a cost-effective alternative to prepreg poles for its canvas boat awnings. The resulting Blacksticks comprise compression-molded carbon fiber braid and epoxy in a unique process.

Read MorePlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

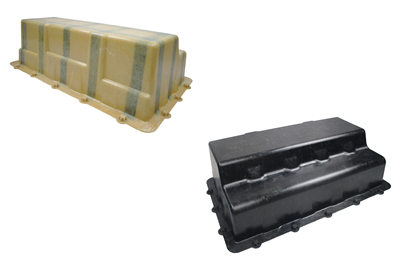

WatchHybrid battery cover: Materials, process decisions

A Q&A with Timo Huber, vice president of HRC’s Advanced Composite Technology Center, discusses material and process considerations for HRC Group’s SMC electric vehicle battery cover research project.

Read MoreSMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

WatchPlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

Read More