Compression Molding

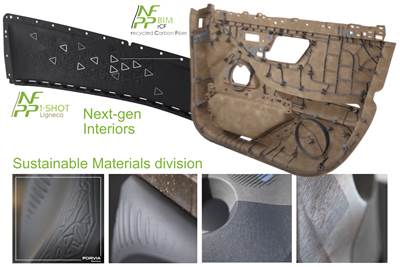

Faurecia advances biocomposites, recyclability, reduced CO2 and sustainability in automotive

Efforts include advancing NAFILean materials family in weight reduction and sustainability, as well as new Sustainable Materials division and R&D Center.

WatchLanxess equips SUVs with Tepex dynalite underbody paneling

Robust thermoplastic panels are 30% lighter than steel designs, features higher resistance to stone impacts or other damage, indicating future applications in electric-, hydrogen-powered vehicles.

Read MoreCDZ Compositi introduces patented 3D Flex Composite

Specialist in structural and aesthetic prepreg press parts enhances 3D shaping and flexibility in composite parts using carbon and other reinforcement fibers.

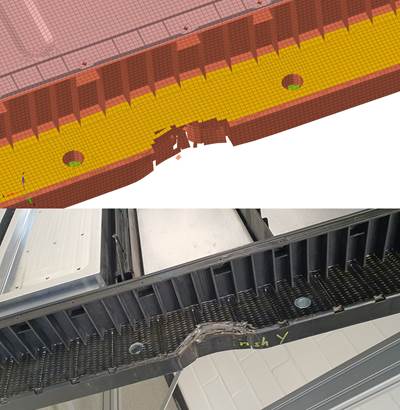

WatchBattery enclosure demonstrator testing proves EV feasibility, launches series production projects

Kautex Textron and Lanxess jointly developed and tested a PA6 technology demonstrator, reinforced with locally placed continuous fiber blanks, which passed all important mechanical, thermal tests.

Read MoreCAMX 2022 exhibit preview: Wickert Hydraulic Presses USA

Wickert Hydraulic Presses showcases its custom hydraulic presses and fully automated press systems for demanding composite manufacturing solutions.

Read MoreCollins Aerospace demonstrates new thermoplastic composites capabilities

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

Read MoreUniFORM: High-quality, high-complex EV battery enclosures at low cycle times, low tooling costs

Stellantis subsidiary CpK Interior Products Inc. recently completed a design challenge to prove out its vacuum-assisted wet compression molding process for CFRP battery trays.

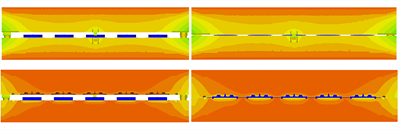

Read MoreSigma Engineering adds compression molding simulation to Sigmasoft Virtual Molding

In addition to a reworked user interface, the full process simulation software now includes the ability to view all thermal influences on the component and in the mold.

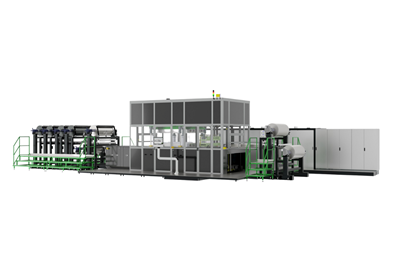

Read MoreCAMX 2022 exhibit preview: Teubert

Teubert highlights enhancements made to its continuous compression molding (CCM) system, including production scale-up, reducing required energy during production, live measurement of pressure distribution.

Read MoreGreenerd designs, engineers new 2,500-ton compression molding press

Productive, reliable molding press features an optimized mold transfer system for improved ergonomic and safety dynamics for operators.

Read More

.jpg;maxWidth=300;quality=90)