Compression Molding

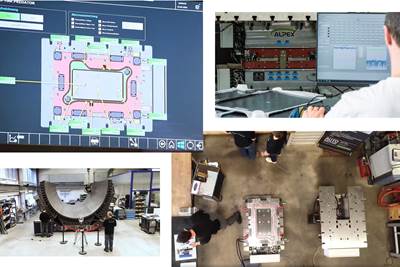

Digitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Read MoreCAMX 2022 exhibit preview: Schuler North America

Schuler’s smart control systems are said to achieve high material savings by reducing waste throughout the material cutting, distribution and forming processes.

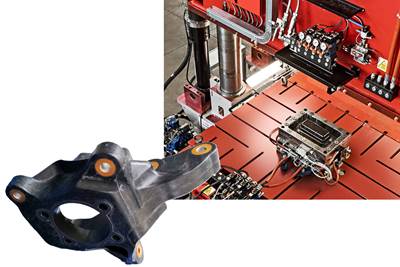

Read MoreA digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

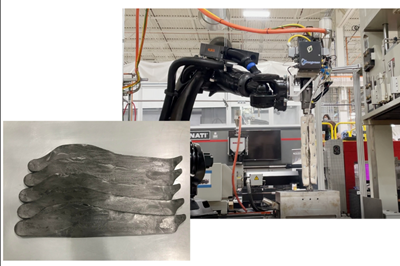

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

WatchCFRTP enables better, greener smartphones

Carbon Mobile’s “monocoque” design eliminates separate case, cover and frame, better protects electronics and simplifies disassembly.

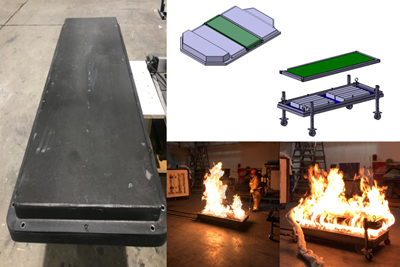

WatchPrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreWickert commissions composite press for ballistic plate production

Wickert reports an increasing interest in complete presses used to produce composites-intensive armor for civilian and military vehicles, ships and aircraft.

Read MorePlant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreTeijin Automotive Technologies to produce pickup box for next-gen Toyota Tundra

One-piece compression molded composite pickup boxes — in addition to the tailgate — will be produced at the company’s Seguin, Texas, facility in three size options.

Read More