Compression Molding

Top 10 CompositesWorld articles of 2021

As this year comes to a close, CompositesWorld is taking some time to reflect on what the year held for those in the composites industry. Take a look at the most popular articles of 2021.

Read MorePlant tour: ATC Manufacturing, Post Falls, Idaho, U.S.

ATC is at the top of the list when it comes to thermoplastic composites and aerostructures manufacturing. CW explains why.

Read MoreComposites Evolution showcases high-performance prepregs, novel thermoplastic UD tapes

Composites Evolution highlights its Evopreg prepreg family, as well as PA6 tapes reinforced with UD carbon fiber for ATL, filament winding and compression molding.

Read MoreHexcel, HP Composites develop carbon fiber Class A body panels

Italian component producer combines composites processing expertise with Hexcel HexPly XF3 surfacing material, HexPly M47 and HexPly M49 prepregs for supersport sedan external body panels.

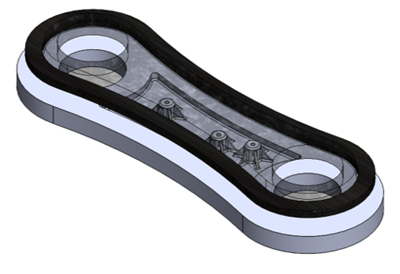

Read MoreIncreasing the composite stack: Co-molding of dissimilar materials

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. (Sponsored)

Watch9T Labs recognized as a Swiss Top 100 Startup company

9T Labs has been awarded third place in the 2021 Swiss Top 100 Startups competition for its hybrid 3D printing technology, which combines 3D printing with compression molding in matched metal dies.

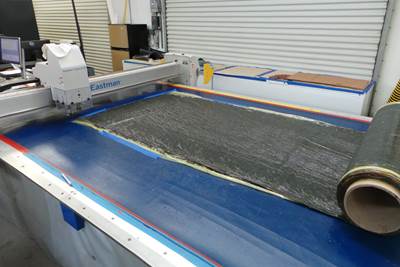

Read MorePrecision Cutting Enables High Speed Composites Molding Process

Automatic cutting of proprietary composite materials is critical for high speed molding of military-grade pressurized camera enclosures.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

Read MoreTroubleshooting thermoforming of thermoplastic composites

Challenges with the thermoforming/stamping process and potential solutions addressing the associated parameters and complex material behaviors.

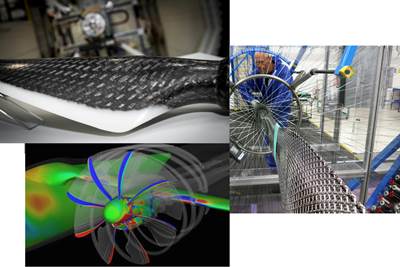

Read MoreDigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms

AMRC aids R&D program including foam thermoforming, complex braiding, thermoplastics and digital twin/thread for higher performance, lower weight with first applications in process.

Read More