Processes

Pultruded window: Glass/polyurethane prototype wins award

Deceuninck Group NV (Hooglede-Gits, Belgium), is at the forefront of composite window frame design and innovation, as evidenced by its recent award for a large, prototype window designed to open like a door.

Read MoreSearching for composites-friendly machine tools

This is IMTS week, where "composites" is a foreign word to much of the machine tool industry. It's not too hard, however, to find suppliers who know their way around composite structures.

Read MoreLeichtbau ist hybridbau

Integrating multiple materials and functions for lightweight construction in the German automotive industry.

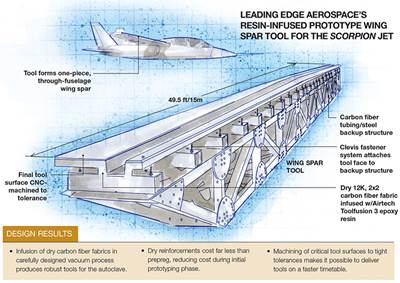

WatchResin infusion produces autoclave-capable tools for Scorpion jet

Leading Edge Aerospace designs and builds cost-effective prototype tools for maverick military aircraft concept.

Read MoreMIT researchers reveal how bonded joints fracture and fail

Moisture reportedly plays crucial role.

Read MoreAre LFRT composites key to auto adoption?

Long carbon fiber-reinforced thermoplastics don't pack the punch of continuous carbon fiber, but they might help spread use of composites in automotive.

Read MoreDisaster-resistant housing: Framing the future

This need in developing nations could be met by a composite structural framing system capable of producing both fortified dwellings and jobs.

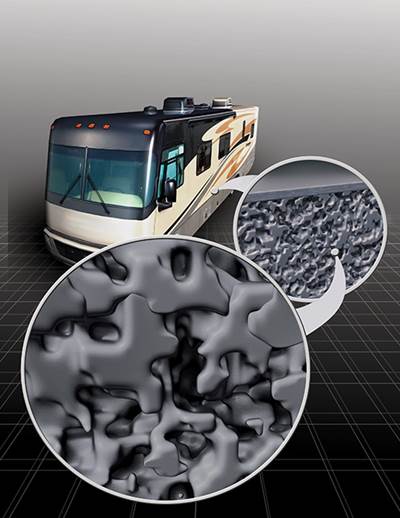

Read MoreMass reduction for mass appeal: FRPs and CMCs in RVs

Composites save weight, speed assembly, improve aesthetics and diminish warranty service and promote sales.

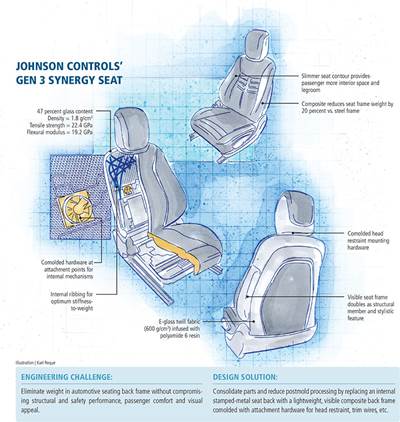

Read MoreSitting pretty: Car seat concept scores a first

Automotive supplier’s reinforced thermoplastic back frame curtails weight and simplifies molding/styling tasks.

Read MoreEvent pavilion: SMC panels ensure architectural authenticity

To expand its services, the High Bullen golf and spa hotel in Devonshire, U.K., converts a little-used tennis facility into a flexible meetings facility, and kept the remodeled structure within the local "heritage" code with simulated mortared stone-like composite panels from Acell Industries Ltd. (Dublin, Ireland).

Read More

.jpg;maxWidth=300;quality=90)