Search Results

Showing 681 – 690 of 1115 results

Composite materials are engineered combinations of two or more distinct materials, merging their individual properties to create a new material with enhanced characteristics. Typically composed of a reinforcing phase (like fibers or particles) embedded within a matrix (often a polymer, metal, or ceramic), composites leverage the strengths of each component to achieve superior strength, stiffness, lightness, or other desirable attributes. Their versatility extends across industries, from aerospace and automotive to construction and sports equipment, where their tailored design and exceptional properties offer solutions for high-performance applications.

Recycling in composites manufacturing is an evolving endeavor aimed at addressing sustainability challenges. Unlike traditional materials, composites often pose recycling complexities due to their multi-component nature. However, innovative techniques are emerging to tackle this issue. Methods like pyrolysis, mechanical recycling, and chemical processes are being developed to efficiently recover valuable components from composite waste, such as fibers or matrix materials.

Flax fiber/bio-thermoplastic composite provide look and feel of wood but higher properties, targeting $80 billion interiors market and, eventually, a wood replacement for construction.

Conducted by Asahi Kasei and Skopos, the November 2022 survey found differing opinions regarding purchasing behavior, automotive sustainability and autonomous vehicles from the top automotive markets in Germany, China, Japan and the U.S.

The former metal component forger seeks the disruptive manufacture of high-performance CFRTP parts using 9T Labs’ Red Series Additive Fusion Solution platform for current and new markets.

KraussMaffei (Hall 6, F61) is featuring several composites manufacturing technologies, covering wet molding, pultrusion, long fiber injection and overmolding.

Dr. Ryan Hahnlen and Dr. Srikanth Pilla will be sharing their collaborative work on a cost-effective CFRTP door assembly, and what the application represents for lightweighting the automotive industry.

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Automated cell manufactures and pre-impregnates continuous-fiber 3D preforms for injection/compression overmolding of parts with complex shapes, and tailored structural properties.

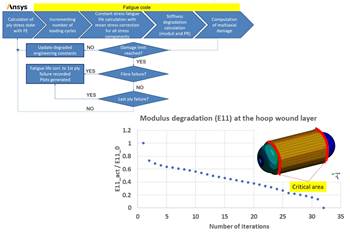

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Suffice to say that JEC World 2022, the “Big Show” for the composites industry, exceeded many expectations. Dale Brosius contemplates pervasive themes, conversations and takeaways from the international event.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.