Processes

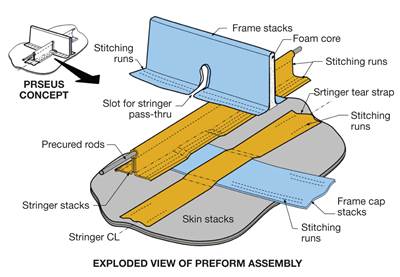

PRSEUS preform for pressurized cabin walls

Over the next few years, NASA and The Boeing Co. (Chicago, Ill.) will build larger and more elaborate pressurized passenger cabin structures for future blended-wing airliners.

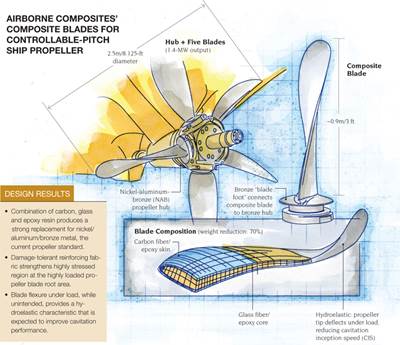

Read MoreComposite propeller for Royal Navy minehunter

Composite-for-metal replacement brings multiple benefits.

Read MoreSoftware speeds tape layer production, optimizes precision

the Siemens Aerospace Center of Excellence's (Elk Grove Village, Ill.) developed the Siemens SINUMERIK 840D CNC system speeds production on a large ATL machine at the former Boeing Wichita plant (now Spirit AeroSystems) in Wichita, Kan.

Read MorePress refurbishment a cost-effective strategy for improving production

When a U.S.-based molder of composite friction materials used in aircraft braking systems recently upgraded its factory capabilities, French Oil Mill Machinery Co. (Piqua, Ohio) agreed to rebuild 10 of the molder’s 400-ton presses

Read MoreAn out-of-autoclave progress report

CW Conferences director Scott Stephenson recalls Dale Brosius’ update on Quickstep’s out-of-autoclave work for the F-35 program.

Read More2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

Read MoreSmall wind gets big

Massive growth, complex blade designs reopen challenging market in wind energy niche.

Read MoreRe-inventing the RHIB: Shock Mitigation

The U.S. Navy’s search for a lighter, load-absorbing rigid-hulled inflatable boat may end with this unconventional design.

Read MoreFiberglass façade: GRP shapes modernize hotel in Spain

The exterior of the Vista Riviera hotel in Benidorm, Spain, has been transformed with a modern twist, thanks to the fiberglass expertise of Miraplas SL (Monforte del Cid, Spain).

Read MoreHigh-speed press cure for high-speed racers

Trapped tooling and compression molding bring cocuring efficiencies to previously autoclave-cured, aerodynamic fins and planes.

Read More