Processes

Infused CFRP: New One-Design paradigm

The Farr 400 opens a new frontier in Grand Prix sail racing, with greater precision at lower cost.

Read MoreItalian racer uses foam sandwich design, Scott Bader adhesive

Boatbuilder Anselmo Mauri has manufactured Revolver 42, a polyhedric monohull speedboat, constructed using high-permforance composites, including foam core sandwich design and adhesive provided by Scott Bader.

Read MoreFire destroys window/door pultruder’s plant

Pultruder Omniglass Ltd.’s manufacturing facility in Winnipeg, Manitoba was destroyed by fire in January of this year.

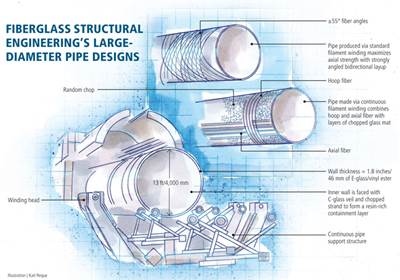

Read MoreMaking continuous composite pipe

The continuous filament winding process was developed in the 1970s by Danish inventor Frede Hilmar Drostholm, and it was commercialized first by Toledo, Ohio-based Owens Corning’s engineered pipe systems business, in partnership with several entities, including Amiantit (Dammam, Saudi Arabia) and Vera Fabrikker (later Flowtite Pipe and Tank AS, Sandefjord, Norway). The ingenious process involves a cantilevered, horizontal rotating mandrel system.

Read MoreDesigning for high pressure: Large-diameter underground pipe

Careful analysis is needed to ensure success of buried composite piping for industrial applications.

Read MorePultruded windows: Rising high?

New pultrudable glass fiber/resin formulations enable window manufacturers to break in to commercial architecture and build market share in residential construction.

Read MoreCured-in-place pipe: UV curing ensures liner performance in leaking pipe

When the Knoxville, Tenn. Utilities Board faced a needed repair of an actively leaking clay sewer pipe, it opted for Reline America's (Saltville, Va.) cured-in-place pipe cured with ultraviolet (UV) light.

Read MoreIntegrated, optimized aircraft door

This composites manufacturer is betting its one-piece 3-D preform and RTM process will trim weight from today’s fastener-intensive “black aluminum” aircraft doors.

Read MoreFormulation flexibility: Direct-SMC

Consortium applies inline-compounding technology to reinvent sheet molding compound.

Read MoreSpare wheel well: Functional integration

Gas-assist injection molding enables one-piece, one-shot thermoplastic composite/metal hybrid.

Read More