Processes

Forging variations

Developed in parallel to the Duqueine Group’s (Massieux, France) MFP process, the high-pressure molding process used by Lentilly, France-based Carbone Forgé is described by Vincent Duqueine as “enabling forging of composites, similar to that done with metals.”

Read MoreForged composites replace complex metal parts

Powerhouse manufacturer’s high-pressure compression molding process forms prepregged CFRP components with forged-metal properties.

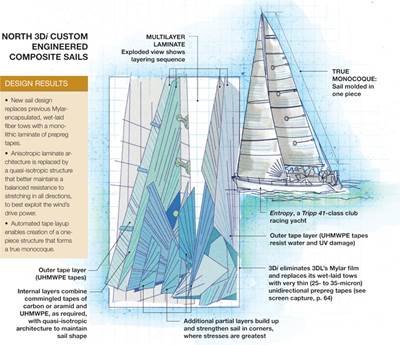

Read MoreCustom-engineered composite performance yacht sails

North Sails introduces 3Di materials and process for structural composite sails.

Read MoreSMC sandwich panels: Lean process opens doors

Patented process enables compression molding at lower pressures, saving capital equipment costs for panel fabrication.

Read MoreComposite solutions: Cutting cost of nuclear-powered subs

Composite-for-metal substitutions cut expense, boost production for Virginia-class submarine program.

Read MoreNew catamaran benefits from structural adhesives, vacuum infusion

Vacuum infusion, SAN sandwich foam cores and structural adhesives help reduce the weight of Mattia's high-performance catamaran yacht by 2,000 kg.

Read MoreThe Plane in Spain

Site tours provide a rare glimpse into the Iberian Peninsula’s aerospace composites sector, with a special focus on Airbus’ activities at Illescas.

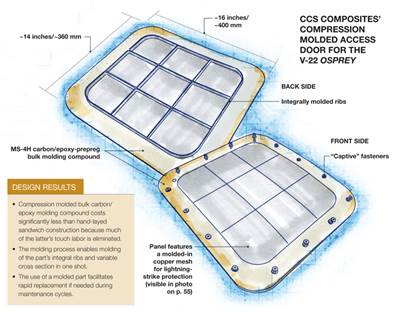

Read MoreRedesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

Read MoreMilling chuck

Machine tooling manufacturer Nikken Kosakusho Europe Ltd. has introduced the X-Treme line of milling chucks, designed specifically for aerospace applications.

Read MoreA hidden revolution: composite rebar gains strength

Fiber-reinforced plastic (FRP) replacing coated steel in more reinforced-concrete applications.

Read More