Processes

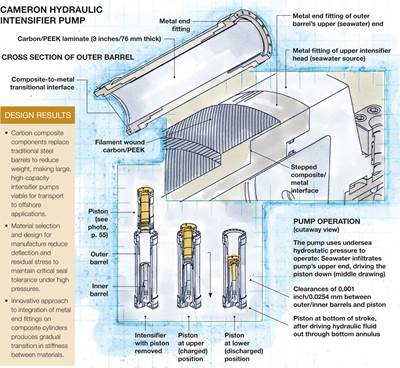

Carbon fiber/PEEK takes hydraulic pump to new depths

A switch from metal to composites reduces weight, minimizes part deflection in ultradeep ocean installations.

Read MoreNew cutting tools for drilling material stacks

Dormer Tools Ltd. (Sheffield, U.K.) has developed veined polycrystalline diamond (PCD) cutting tools for drilling applications that involve stacked materials in aircraft wingskin assemblies.

Read MoreTough resins for aggressive environments

New thermoset systems drive composites deeper into markets where fire, corrosion, stress and fatigue are ever-present threats.

Read More3-D preforms: Fast, efficient blade-root manufacture

To expedite the blade root manufacturing process for wind turbine blade manufacturers, 3TEX Inc. (Cary, N.C.) has developed RapidRoot, a 3-D preform.

Read MoreHeavy-duty infusion: Scaling up for scrubbers

Infused 3-D woven fabric preforms best steel in beams and unitized deck structures built for the caustic confines of massive flue gas desulfurization systems.

Read MoreQ&A: Manuel Torres Martinez

At the 2011 JEC Composites Show in Paris, CT had the opportunity to interview MTorres Group chairman Manuel Torres Martinez, excerpts from which appear here.

Read MoreThermoplastic composites: Primary structure?

Yes, advanced forms are in development, but has the technology progressed enough to make the business case?

Read MoreMicrowave: An alternative to the autoclave?

Aerospace composites manufacturer GKN evaluates microwave oven practicality and cost-effectiveness.

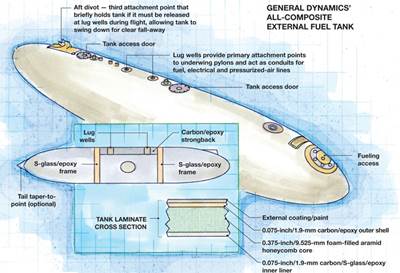

Read MoreCarrier-capable, all-composite external fuel tank

Legacy product positions builder for a shot at an F-35 contract.

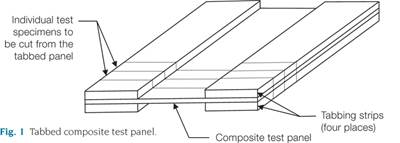

Read MoreTabbing composite test specimens: The how

The when and why of tabbing composite test specimens were the subjects of my previous column (see “Tabbng composite test specimens: When and why," under "Editor's Picks," at right), which included a discussion of tabbing materials, tab thickness and taper angle, and adhesive selection.

Read More