.jpg;maxWidth=250;quality=70)

Peggy Malnati MMT, Contributing Writer

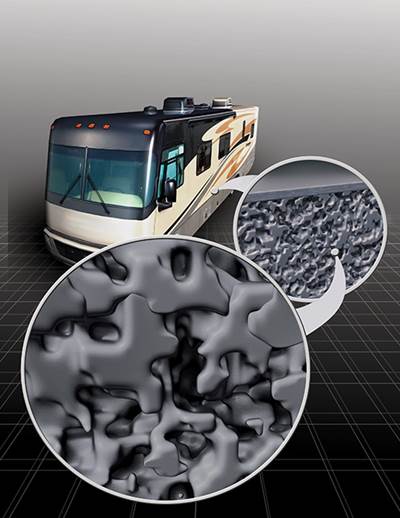

Mass reduction for mass appeal: FRPs and CMCs in RVs

Composites save weight, speed assembly, improve aesthetics and diminish warranty service and promote sales.

Read MoreComposites for heavy truck: Tough-duty inspection cover

Thermoplastic composite reduces weight, cost, corrosion, extends maintenance intervals.

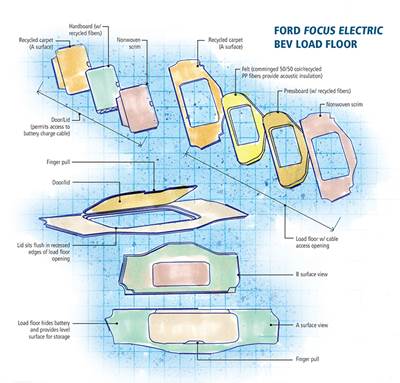

Read MoreNatural fiber composite drives automotive sustainability

Coir felt greens an EV, improves lives in developing world.

Read MoreRevisioning the Viper: Clamshell hood challenge

Autoclave-cured carbon-fiber prepreg hood/fender combo proves as technically formidable as it is visually stunning.

Read MoreCommercial trucking: Streamlining the Big Box

Glass fiber-reinforced thermoplastics help commercial trucking industry optimize weight, fuel and cost savings.

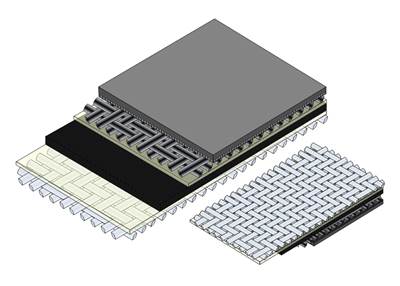

Read MoreEvolution of tailored D-LFT

In the past two decades, two competing composite technologies — sheet-form glass-mat thermoplastic (GMT) and pelletized long-fiber thermoplastic (LFT) — led to the development of a new form of glass-reinforced thermoplastic composite.

Read MoreHybrid thermoplastic molding: Toughening automotive composites

Tailored D-LFT with continuous and discontinuous glass offers best combination of strength, moldability.

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

Read MoreClass A CFRP body panels: Six-minute cure

Gurit CBS-based laminate/process combo mints parts with twice the thermal performance in one-sixth the time.

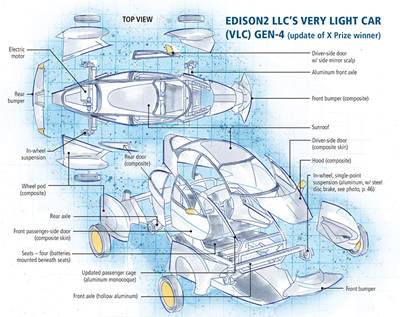

Read MoreVery Light Cars: Driving the future

X Prize-winning technology aims to change vehicle architecture.

Read More