.jpg;maxWidth=250;quality=70)

Peggy Malnati MMT, Contributing Writer

Under the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreMaintaining fiber length in complex 3-D designs

Award-winning composite pallet showcases new LFT molding process from South Africa.

Read MoreSPE's ACCE 2010 preview

Charting a composites course through the auto industry’s “perfect storm.”

Read MoreInterior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

Read MoreQuiet revolution: Composites in EVs

Startup automakers make use of composite body/chassis components to extend the range of hybrid-electric and battery-electric vehicles.

Read MoreEngineering Insights: Not Your Father's EV

A stylish composite body makes the world's first all-electric sports car not only lean and green but efficient and fast as well.

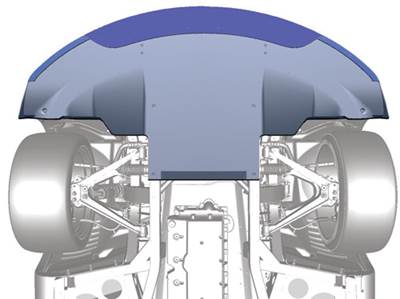

Read MoreUBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

Read MoreECO Elise concept: Lean, speedy and green

Focus on use of sustainable materials and cleaner manufacturing processes promises future Lotus customers “almost-guilt-free” performance.

Read MoreCorvette's carbon hood creates shock and awe

North America’s first mass-produced, all-CFRP hood raises the bar for production sports cars.

Read MoreSPE's ACCE 2009 Show Preview

The Society’s 2009 Automotive Composites Conference & Exhibition charts an industry at a crossroads.

Read MoreComposite wing key to high-speed stability

First mass-produced CFRP wing helps supercar achieve downforce and lateral acceleration values superior to many GT racing cars.

Read More