Search Results

Showing 171 – 180 of 1090 results

A comprehensive lifecycle, cost and carbon emissions study on carbon fiber molds, produced for New York’s concrete Domino building, cites economic benefits over wood alternatives.

Accepting carbon fiber waste materials now, Carbon Fiber Recycling will recycle 2,000 tons of carbon fiber waste per year at its Tennessee facility.

The U.K.’s NCC with partners B&M Longworth and Cygnet Texkimp achieve continuous carbon fiber recovery in a significant first step to deliver sustainable composite pressure vessels for the hydrogen market.

For decades, carbon fiber has failed to break through into mainstream automotive applications as the composites industry has hoped it would. Alternative composite applications suggest future opportunities still remain bright.

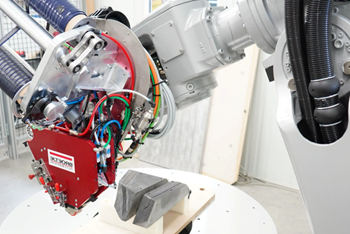

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

LiteSIP panels and modules enable framing in days, cutting structural labor and total cost by up to 70% and 30%, respectively, while increasing energy efficiency and durability.

Longworth’s DEECOM process for composites recycling claims to produce intact fiber and resin reclamation with near-virgin properties.

Life cycle assessment (LCA) will aid in calculating carbon emissions for all of its carbon fiber filament applications.

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

During the one-day virtual event on April 17 from 11 a.m. to 3:30 p.m. ET, seven industry experts will provide insight into hot topics like waste reduction, energy efficiency, bio-materials and recycling.