Celanese Corporation

222 W. Las Colinas Blvd.

Ste. 900N

Dallas, TX 75039 US

(800) 833-4882 | 859-372-3244

info-engineeredmaterials-am@celanese.com

celanese.com/engineered-materials/products/celstran-cfrt.aspx

About Celanese Corporation

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Celanese Corporation Supplies the Following Products

- Acetal

- Consulting, materials

- Nylon (polyamide)

- Other thermoplastics

- Polybutylene terephthalate (PBT)

- Polycarbonate

- Polyester

- Polyether ketone family (PAEK, PEKK, PEEK)

- Polyetherimide (PEI)

- Polyimide

- Polyphenylene sulfide (PPS)

- Polypropylene (PP)

- Thermoplastic, long fiber-reinforced (LFRT)

- Thermoplastic, short fiber-reinforced

Editorial, News, and Products

-

Celanese to acquire majority of DuPont’s mobility and materials business

Celanese will acquire nearly all of DuPont’s engineering thermoplastics, as well as specialty nylons, polyesters and elastomers, much of it devoted to automotive.

-

SPE Automotive Division names 36 finalists for annual Automotive Innovation Awards Gala

Category and grand award winners selected by the Blue Ribbon judging round Oct. 1 will be announced during the gala on Nov. 10, 2021. Submissions are described below.

-

AIM3D multi-material 3D printer targets precise, cost-effective polymer processing

Extrusion 3D printer offers considerably faster build rates and can print up to three different materials in parallel for metals, ceramics and high-temperature plastics such as PEEK and PPS with or without fiber filling.

-

People in Composites: May 2021

Illium Composites, Boom Supersonic, Hexion, AOC, KraussMaffei, Composites Integration and SPE announce new hires within the composites manufacturing industry.

-

Bespoke process produces composite brake pedal every minute

Three composite materials are used to create structural composite member that meets demanding mechanical requirements.

-

Thermoplastic composite structure replaces metals on safety-critical brake pedals

First all-composite brake pedals developed by Boge Rubber & Plastics Group are lighter, stiffer, stronger and offer improved driving haptics.

-

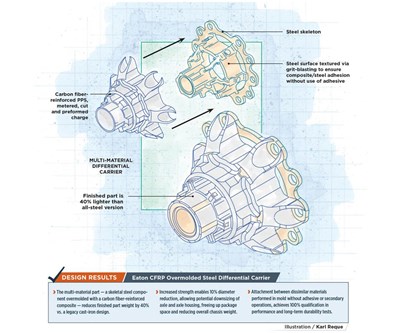

Metal + composite = Less weight, more room

Global supplier develops scaled design approach for metal/composite hybrids in highly loaded automotive applications.

-

Small companies, long-term impact

In a time known for owner “exit strategies,” longevity in family-owned composites businesses is heartening.

-

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

-

Thermoplastic composite pressure vessels for FCVs

U.K. consortiums address durability, weight, cost of high-pressure tanks for hydrogen fuel-cell powered vehicles.

-

SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

-

Hybrid thermoplastic molding: Toughening automotive composites

Tailored D-LFT with continuous and discontinuous glass offers best combination of strength, moldability.

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

High-temp thermoplastics: Higher Expectations

As the drive to greater fuel efficiency under the hood catches fire, fiber-reinforced thermoplastics prove they can take the heat.

-

2011 High-Performance Resins Highlights

Attendees reviewed the current state of advanced resin technology and the tests that lay ahead for expanding composites into new applications and markets.

-

JEC Paris 2011 highlights

The news from this annual Parisian in-gathering of composites professionals is heavily weighted toward automotive lightweighting.

-

Under the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

-

Interior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

-

SAMPE 2010 Seattle Showcase

SAMPE’s first-ever foray into Boeing Country wrapped up with the M&P organization’s biggest draw this decade.

-

Report from Detroit: NAIAS highlights

Electrics and hybrids make headlines, composites suppliers see hopeful signs after OEM restructuring.

-

UBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

-

Wichita welcomes SAMPE Tech

The Society’s Fall Conference flourishes in one of the epicenters of U.S. aerospace activity.

-

Composites fuel growth of fuel cell technology

Composite components in hydrogen fuel cell systems help handle higher heat and reduce stack size.

-

Thermoplastic tubulars: Robust flexibility for offshore wells

In the oil and gas industry, a fiber-reinforced thermoplastic composite pipe (TCP) system from Airborne Composite Tubulars (The Hague, The Netherlands) is providing a less-expensive alternative to the traditional “rig” for flushing subsea wellhead stacks and injecting glycol under pressure.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

Thermoplastic composites: Inside story

Reinforced thermoplastics buy their way into structural aircraft interior components.

-

SAMPE Europe/JEC Composites 2009 preview

SAMPE Europe’s 30th annual spring conclave and the nearby JEC Composites Show characterize the latest in material and process technologies.

-

What's new in automotive front-end modules?

Composite and hybrid composite/metal solutions reduce cost and weight and increase assembly efficiency on passenger vehicles.

-

Reinforced Thermoplastics: LFRT/GMT Roundup

Recent advancements in these reinforced thermoplastic technologies are expanding their performance, enabling new applications.

-

Reinforced Thermoplastics: LFRT vs. GMT

As the suppliers of long fiber-reinforced thermoplastics and glass-mat thermoplastics battle for market supremacy, the winner is … the composites OEM.

-

Thermoformable Composite Panels, Part II

Preconsolidated sheet stock for load-bearing applications features continuous fiber - not only glass, but carbon and aramid as well.

-

LFRT Uncovers Hidden Value For New Jeep Vehicle

Long-fiber thermoplastic composite fulfills engineering and assembly plant requirements for multifunctional door module.

-

Thermoformable Composite Panels, Part 1

Preconsolidated fiber-reinforced thermoplastics offer short cycle times, tailored properties, recyclability and lower cost.

-

In-Mold Decorating Dresses Up Composites

Automotive/industrial markets foster development of finishing techniques that eliminate costly paint lines.

-

Composites Make Large Difference In small Medical, Dental Applications

Surgical instruments and dental restoratives take advantage of polymers with glass-fiber and nanomaterial reinforcements.

-

Jaguar XJ Structures Celstran LFRTs Thermoplastics

Although Jaguar Cars Ltd.'s (Whitley, U.K.) newly redesigned Jaguar XJ has a body made from aluminum rather than sheet steel, the automaker and its automotive systems supplier Automold Ltd. (Gloucestershire, U.K.) used Ticona's (Summit N.J., U.S.A., select 296) Celstran long-fiber-reinforced thermoplastic (LFRT) in

-

Thermoplastic Composites Making An Impact

Product/process developments accelerate use of long-fiber-reinforced thermoplastics in automotive and industrial markets.