Injection/Overmolding

Porcher Industries launches new range of flax fiber-based thermoplastic composites for automotive

Composite stiffeners, sold as textiles, are made primarily of flax fibers grown, selected, mixed and woven in France for modern, durable and environmentally conscious applications.

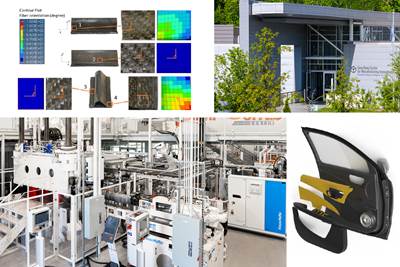

Read MoreClemson Composites Center: Working with industry to transform composites

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

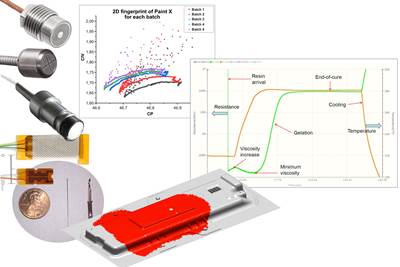

Read MoreSensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

WatchPlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

WatchSABIC, Dongfeng Motors produce composite truck-mounted toolbox

Thermoformed glass fiber-reinforced PP laminate inserts are overmolded with Stamax resin for a 30% lighter part.

Read MoreTepex composite opens up new opportunities for electric skateboards

The continuous fiber-reinforced thermoplastic is used for a trough-shaped skateboard deck application, notable for its high torsional and bending strength, light weight and moisture protection.

Read MoreRiding pretty: Hybrid upper control arms move to pickups

Short-glass/PA6 with metallic inserts reduces mass, running torque, joint wear on the Ram 1500 half-ton pickup truck.

Read MoreRobotic injection molding for functionalized composites

Anybrid enables compact, flexible hybrid injection molding/overmolding for smaller series and larger components.

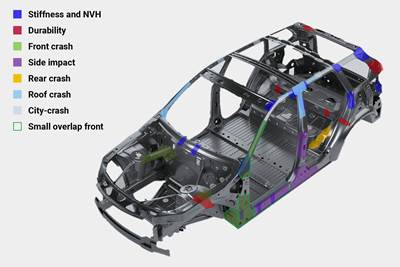

WatchComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

Read MoreWEAV3D, GAA partner to expand structural composite opportunities in automotive sector

Tunable, composite lattice structures produced via patented automated weaving process able to support automotive volumes of hundreds of thousands of units per year.

Read More