National Composites Week

Isobaric double belt press is well suited to continuous production

CAMX 2023: Flexible and robust double belt presses from Held Technologie are adaptable to various base composite material requirements to produce top-quality, long-lasting products.

Read MoreDymag, Hankuk Carbon work with Hyundai on hybrid composite wheels

Full specifications of the bespoke prototype wheel for Hyundai’s N Performance vehicles will be revealed later this year.

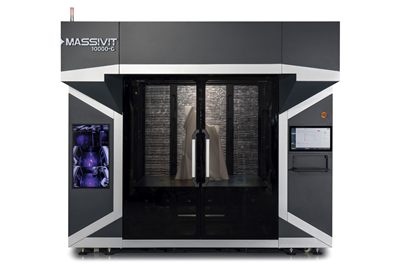

Read MoreLarge-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

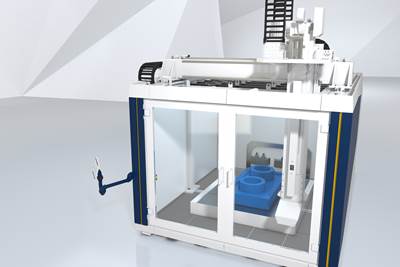

Read MoreKraussMaffei launches large-scale 3D printer, print-on-demand services

PowerPrint, capable of using fiber-reinforced compounds, combines design freedom and cost efficiency for large-format printing applications. It is available for purchase or serviced through KraussMaffei.

Read MoreImpulse Space secures $45 million to support vehicle development, production

Developer of in-space transportation vehicles using CFRP tanks raises capital investment from Raytheon Technologies (RTX) Ventures.

Read MoreAFPT, Alformet advance bending of thermoplastic composite tubes

Specialists in AFP and LATW discuss process and lessons learned for new applications in CFRTP parts.

Read MorePE adhesive creates strong, fast bonds to low surface energy substrates

IPS Adhesive’s Scigrip brand introduces SG400LSE, a transluscent, low-color adhesive that has proven its ability to bond to FRPS, metals, plastics and other polymers.

Read MoreDassault Aviation becomes a Nadcap Subscriber

Dassault has joined other aerospace prime contractors that have demonstrated design authority and control over supplier quality.

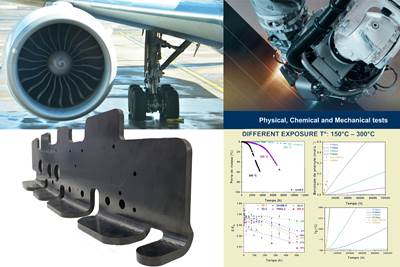

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

WatchSGL Carbon statement indicates decrease in carbon fiber demand for wind

According to preliminary figures for H1 2023, the Carbon Fiber business unit saw a 28.9% decline in sales, balanced by Graphite Solutions, Process Technology and Composite Solutions segments’ better-than-expected earnings.

Read More