Processes

Out-of-autoclave manufacturing: The green solution

Regular HPC columnist Dale Brosius calls attention to the environmental benefits of out-of-autoclave processing.

Read MoreRVB Infusion = Light RTM?

There is some difference of opinion as to whether parts infused under reusable vacuum bags (RVBs) are the equivalent of those produced by Light resin transfer molding (RTM). See why.

Read MoreRVB insider insights

Experts in reusable vacuum bag technology share insights into bags adapted for autoclave use.

Read MoreReusable vacuum membranes: Coming of age?

Durable custom elastomeric bags cut consumables cost and boost rate production.

Read MoreBus station pavilion: A marriage of design and manufacture

Architectural design studio and boatbuilder cooperate to make this passenger terminal "first" a first-class showpiece.

Read MoreSciGrip MMA to replace epoxy adhesive in wind blades

Methyl Methacrylate to offer up to 40 percent reduction in blade assembly cycle time plus address current maintenance issues due to variable bondline thickness.

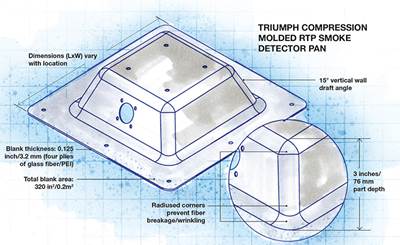

Read MoreCompression molding mass out of aircraft interiors

Continuous carbon fiber-reinforced thermoplastic lightweights smoke detector pan and slashes production cycle time.

Read MoreCo-infused stringers and carbon fiber at Ft. Lauderdale Boat Show

Midnight Express Boats takes almost 4,000 lb out of its newest model, the 39S, with a switch to infusion and better optimized laminates.

Read MoreSewer system: Corrosion protection for buried odor-control ductwork

ECS Environmental Solutions (Belton, Texas) was contracted to provide odor control equipment and relied on Vipel vinyl ester resin from AOC Resins (Collierville, Tenn.) for more than 1,000 ft/305m of fiberglass ductwork and accessories.

Read MoreCast polymer categories

The cast polymer industry is multifaceted. Its many products, however, can be grouped into three general categories, differentiated by the materials and manufacturing methods used to make them.

Read More