Processes

Aiming infusion at the application

With so many process variables to play with, how do you know which new solutions that promise better, faster infusion are right for your application?

Read MoreCutting train doors with precision

GFMI Aerospace & Defense uses waterjet cutting technology to produce glass fiber/epoxy door panels for a major rail car manufacturer.

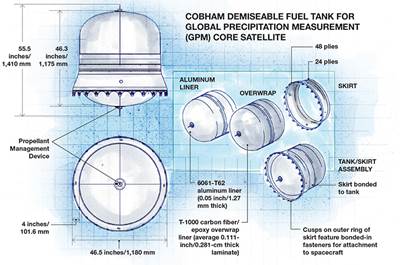

Read MoreSpace mission maximized via minimized survivability

CFRP design and manufacturing flexibility prove key in first spacecraft fuel tank designed to disintegrate upon reentry for improved mission efficiency and debris mitigation.

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

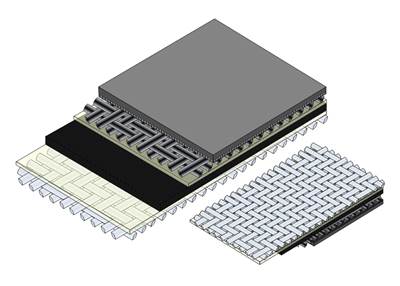

Read MorePress-molding method emulates autoclave

Rubber tool insert avoids consolidation pressure “dead zones” and slashes cost.

Read MoreClass A CFRP body panels: Six-minute cure

Gurit CBS-based laminate/process combo mints parts with twice the thermal performance in one-sixth the time.

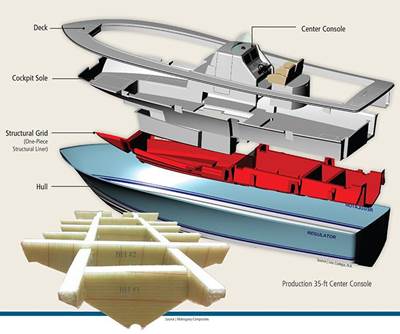

Read MoreThe structural grid: Prefabrication

Digitally designed and cut, preformed and preinfused stringers and bulkheads reduce boat weight, labor and cycle time and improve boatbuilder process control.

Read MoreComposites slake the world's thirst

As the global thirst for drinkable water increases, the composites industry is drinking in the tremendous possibilities in seawater desalination.

Read MorePaddleboard productivity: Adhesively bonded hull/deck is key

Dragonfly Boatworks LLC's (Vero Beach, Fla.) new standup paddleboard for fly fishing is built without fasteners, with the aid of SG200-40 methacrylate adhesive from SCIGRIP Smarter Adhesive Solutions (Durham, N.C.).

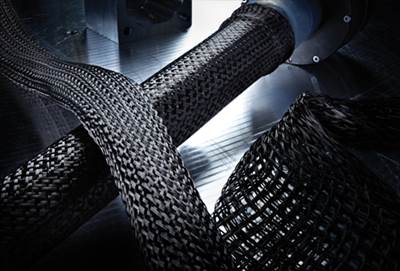

Read MoreAn impec-able bike frame: Handmade by machine

Long on technology firsts, this optimized, automated manufacturing process produces nothing short of the “perfect” bike frame.

Read More