Processes

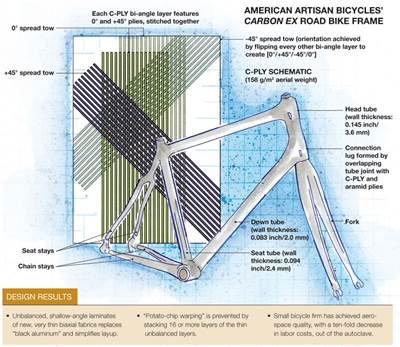

Bi-angle fabrics find first commercial application

Bicycle manufacturer sees dramatic productivity gains using unbalanced fabrics conceived at Stanford University and manufactured by Chomarat.

Read MoreInfusion of aerostructures: Doubling down on the details

For this carbon-fiber composite manufacturer, little things make big differences in a not-quite-new but still novel double-bag infusion technique.

Read MoreDouble-bag infusion attracts new customers

Carbon Fiber Composites Inc. (CFC, Hurricane, W. Va.) president Brian Alley credits the double-bag infusion process with attracting two new aircraft customers.

Read MoreExceeding the Limits

Three novel fiber-reinforced, high-temperature thermoplastics promise part designers a broader means to push past performance barriers.

Read MoreOff-grid turbine: Helix in the wind

This new composite twist on the vertical-axis wind turbine makes no small impact on the private power market.

Read MoreMilking platforms: Composites transform New Zealand cow sheds

Waikato Milking Systems (Hamilton, New Zealand) introduced its Centrus composite milking platform in 2009 and, since then, has installed 24 platforms at customer sites. They're made via RTM Lite.

Read MoreShop practice impacts drilling success

When you're drilling holes in composites, there are many variables that must be considered. Some factors that have an impact on success are process and shop driven. The following are industry best practices that have been demonstrated to maximize hole quality and drilling efficiency with composites.

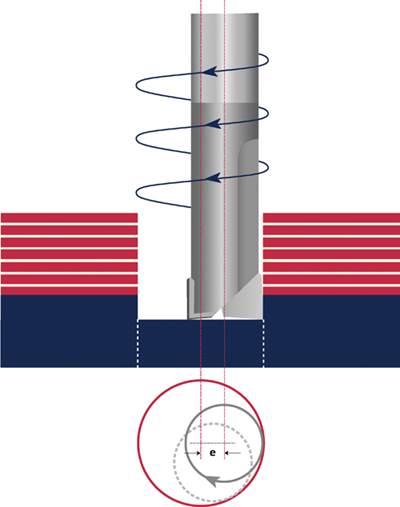

Read MoreOrbital Drilling enables “one-up assembly”

Orbital Drilling, a technology patented by Novator AB (Spånga, Sweden) offers multiple hole sizes from a single drill tool.

Read MoreOnline access to machine tool knowledge

Machine tool manufacturers have developed a variety of online tools that give customers in the composites industry access to lessons learned, best practices and information about the latest machine tool technologies.

Read MoreOptimizing, customizing composites hole drilling

Matching the drill tool to the job can save thousands of man-hours and millions of dollars.

Read More

.jpeg;maxWidth=400;quality=70)