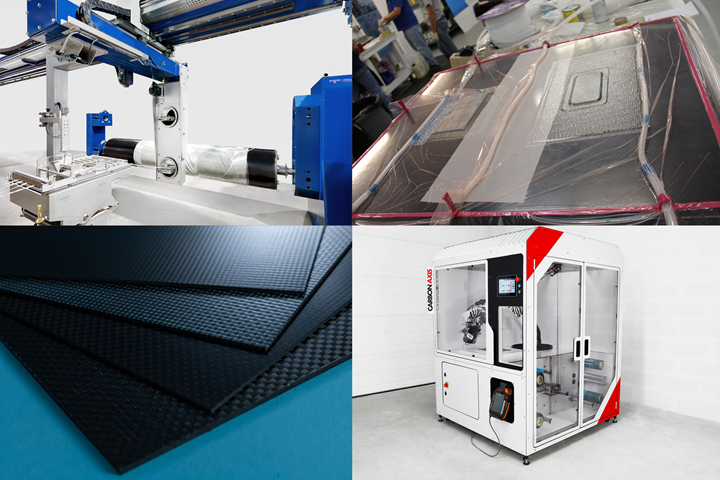

Photo Credit: (top left) Autonational, (top right) Abaris Training Resources, (bottom left) ACG Chemicals and (bottom right) Carbon Axis.

It is with great anticipation that composites professionals plan to gather for CAMX 2021, taking place Oct. 19-21 in Dallas, Texas, U.S., at the Kay Bailey Hutchinson Convention Center. In addition to traditional conference sessions and tracks that cover a wide range of topics, Featured and Camp Fire Sessions, and the presentation of the trade show’s acclaimed CAMX Awards and Awards in Composites Excellence (ACE) program, this year’s North America’s largest composites and advanced materials trade show also boasts more than 360 exhibitors and their products.

What follows is Part 1 of an exhibit preview lineup that highlights CAMX exhibitors and the software, materials, equipment and services they will feature in their booths, as solicited and received by CW. Company names are linked directly back to the original preview article.

Part 2 of this compilation will feature the rest not listed here.

Exhibit previews:

- A&P Technology : A&P Technology’s new product offerings include slit tape thermoplastic fabrics, powder coating and lamination capabilities. The company also highlights TX-45, which combines the mechanical performance of T1100G 71E 12k carbon fiber and offers significant cost savings.

- Abaris Training Resources: Abaris Training is highlighting current and new courses for advanced composites training, as well as engineering consultation services and other technical assistance.

- Acrolab: Acrolab Ltd. highlights its thermal products and system design capabilities, with applications in composite tooling and processing.

- ACG Chemicals: AGC Chemicals’ Fluon+ fluoropolymers are ideal for composites applications that require a durable, lightweight material, such as automobiles, aircraft and sports products.

- Airborne: Airborne presents its integrated automated kitting system, which can pick composites plies directly from the conveyor cutter to sort, sequence and store them in a compact and fast buffer station.

- Alpine Advanced Materials: Alpine Advanced Materials unveils HX5 billets for faster, more exact advanced material prototyping capabilities.

- Armacell: Armacell features its eco-friendly, recycled PET bottle ArmaPET foam solutions for composite parts in a variety of end markets.

- Autonational: Autonational highlights its capabilities in automated filament winding and CNC machining, including a recent case study from a utility vehicle manufacturer.

- Avient: Avient highlights its wide-ranging thermoplastic and thermoset composite materials portfolio, and three presentation topics.

- Boston Materials: Supercomp, ZRT and Bimetal are three of Boston Material’s z-axis carbon fiber products developed via its patented magnetic alignment process.

- C.A. Litzler: C. A. Litzler thermoplastic prepreg machines are designed to enable lower-cost, thermoplastic prepregs for automotive and aerospace applications.

- C6 Composite Tooling: C6 Composite Tooling showcases a saw that is capable of radial cutting and a countersinkng tool with an aggregate head, which gives precise control of riveting.

- Calyxia: Calyxia’s featured microencapsulation technology can protect reactive, functional and optical additives even in extreme temperature and shear processing conditions.

- Carbon Axis : Carbon Axis showcases compact AFP solutions for the preforming of small parts with the XCell, XPlace mk2 and IdeaLab.

- Cevotec: Cevotec conceptualizes the Samba PV, an automated fiber layup system that combines filament winding with automated fiber patch placement for optimized composite pressure vessel production.

- CGTech: CGTech is demonstrating VERICUT 9.2 simulation, composites and additive manufacturing capabilities.

- Cimbar Performance Materials: Cimbar Performance Materials’ halogen-free ATH solution for thermoset applications reduces resin costs in formulation, provides better wetout and faster line speeds and improves mold flow.

- Composites Horizons: Composites Horizon LLC presents capabilities in high-temperature composite structures and assemblies manufacturing, including polyimides and CMCs.

- Cygnet Texkimp : Cygnet Texkimp hopes to accelerate the use of composites in hydrogen technology with its new Filament Winding Innovation Hub.

- DowAksa: DowAksa exhibits its product portfolio, which ranges from carbon fiber to downstream converted materials, such as pultruded laminates, and thermoplastic and thermoset derivatives.

- Eastman Machine: Eastman Machine demonstrates full automation for small spaces with the latest configuration of its Eagle-C125 conveyor cutting system and the versatile and adaptable oscillating tool head.

- EconCore: EconCore highlights new production capabilities for recycled and thermoplastic core products, and seeks new partnerships.

- Elemental Coatings: Elemental Coatings’ products minimize ice buildup, improve safety, decrease downtime and mitigate the high cost of many de-icing practices.

- Elliott Company: Elliott Company’s offered urethane closed cell foam is compatible with processes including hand layup, spray-up, vacuum infusion, RTM, lamination, pultrusion and filament winding.

- Engineering Technology Corp: Engineering Technology Corp. features its diverse product and service portfolio, including its standard and custom filament winding equipment lines, ready-made integration options and new FWC10 control system.

- Ensinger: Ensinger exhibits a wide portfolio of products and services for thermoplastic composites, including its Tecatec materials range and polymer pulverizing and development services.

- Europe Technologies: Europe Technologies highlights its robotic finishing cells and ultrasonic cutting solutions.

- Fives Composites & Automated Solutions: Fives Composites & Automated Solutions has developed a major upgrade to the company’s Charger ATL product, introduces the Robotic Viper AFP system and offers it’s inspection system for real-time laminate inspection.

- Gascogne Flexible: Gascogne Flexible presents a tight release valve for ATL applications, a low coefficient of friction, solvent-free release liner and a high-porosity kraft paper for thin-ply prepreg applications.

- General Plastics: General Plastics Manufacturing Co. demonstrates its LAST-A-FOAM products, custom molding capabilities and high-temperature tooling board for a range of industries and applications.

- Georgia-Pacific Chemicals: Georgia-Pacific presents new technologies for reducing formaldehyde in phenolic resins and enabling applications in electric vehicles and other industries.

- Gustav Gerster GmbH & Co. KG: Gustav Gerster’s TechTex corner reinforcements and resin distribution tape optimize the structure of composite components.

- Hawthorn Composites: Hawthorn demonstrates its co-cured wing structure that was made using dry carbon fiber application, overbraiding, liquid infusion and its Smart Tooling.

- Helicoid: Designed for toughness and impact resistance, Helicoid Industries’ biomimetic fiber distribution technology, Helicoid, enhances performance of composite parts.

- Heraeus Noblelight: Heraeus Noblelight showcases its humm3 pulsed light heating technology and infrared heating solutions.

- L&L Products: L&L Products is spotlighting a set of new two-component, ambient temperature-reacting materials that can be used in a range of applications.

- Leuco Tool Corp.: Leuco’s PCD-tipped drills, routers and end mills are designed for a variety of composites-based projects.

- LEWCO Inc.: LEWCO Inc. demonstrates its line of industrial ovens for the composites industry, including batch ovens, composite curing ovens, conveyor ovens, field assembled ovens and drum and tote heaters.

- LUM Industry: LUM Industry specializes in the design and manufacture of highly precise pultrusion dies and molds for glass, carbon fiber or thermoplastic profiles.

Related Content

CAMX 2023 abstract, award nomination applications are open

To participate in this year’s composites and advanced materials event in Atlanta, Georgia, consider submitting a technical paper/education session abstract by March 8th, or applying for the CAMX/ACE Awards by July 13th.

Read MoreWinding software developed for filament winding machines

CAMX 2023: Roth Composite Machinery focuses on automation, safety and time savings.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read More"Good Day, CAMX" to discuss current challenges and future opportunities

On Nov. 1, CAMX 2023 presents an engaging and interactive discussion between Composites One’s Marcy Offner and CW’s brand VP Jeff Sloan concerning the current composites industry landscape.

Read MoreRead Next

CAMX 2021 exhibit preview

The composites industry is gearing up for CAMX 2021 in Dallas, Texas, the first in-person major trade event in more than two years.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More