Search Results

Showing 711 – 720 of 1116 results

Composite materials are engineered combinations of two or more distinct materials, merging their individual properties to create a new material with enhanced characteristics. Typically composed of a reinforcing phase (like fibers or particles) embedded within a matrix (often a polymer, metal, or ceramic), composites leverage the strengths of each component to achieve superior strength, stiffness, lightness, or other desirable attributes. Their versatility extends across industries, from aerospace and automotive to construction and sports equipment, where their tailored design and exceptional properties offer solutions for high-performance applications.

Recycling in composites manufacturing is an evolving endeavor aimed at addressing sustainability challenges. Unlike traditional materials, composites often pose recycling complexities due to their multi-component nature. However, innovative techniques are emerging to tackle this issue. Methods like pyrolysis, mechanical recycling, and chemical processes are being developed to efficiently recover valuable components from composite waste, such as fibers or matrix materials.

IDTechEx gives an overview of the solutions that currently exist for hydrogen storage and distribution, and how these two components are vital to ensuring the full potential of this rapidly growing sector.

9T Labs has been awarded third place in the 2021 Swiss Top 100 Startups competition for its hybrid 3D printing technology, which combines 3D printing with compression molding in matched metal dies.

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

U.K.-based manufacturer joins with SustainableX to address the negative ecological effects of post-process painting of composite components and find more sustainable solutions.

As Dale Brosius winds down his Perspectives & Provocations column, he reminisces on its start in 2013 and offers some parting thoughts on the trends and technologies that are shaping the composites industry.

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

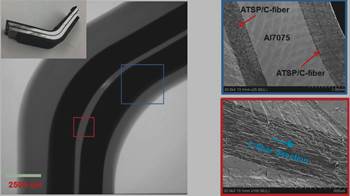

Aromatic thermosetting copolyester offers unique properties, availability in multiple form factors.

As the CAMX media sponsor, CompositesWorld reported on several new or improved developments on display, from CAMX Award and ACE Award winners, to the keynote speaker and interesting technologies.

New focus on high-temperature thermoplastic tapes and multi-layer sheet laminates for aerospace, automotive and other demanding market segments.

Front wings and undertray comprise the honeycomb core material, the latter reducing wing weight by 26% compared to the previous year, and able to withstand forces 1,000 times its own weight.