ATL/AFP

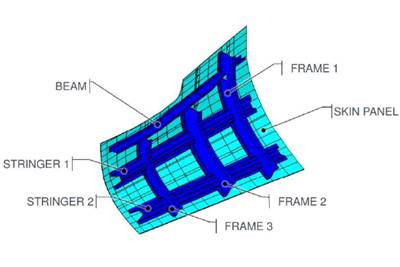

FRAMES: Full-scale thermoplastic composite aircraft rear-end demonstrator

Clean Sky 2 project led by ESTIA-Compositadour will develop enabling technologies for optimum rear fuselage and empennage.

Read MoreAddcomposites and Effman partner to provide AFP cells for SMEs

Aim is affordable, enclosed composites manufacturing cells for many different processes (AFP, grinding, buffing, sanding, drilling) in North American market.

WatchCompoTech launches standard range for carbon finer epoxy beams

Produced via AFP and precision press molded results in a high-strength carbon epoxy composite beam with 10-15% higher stiffness in the axial direction.

Read MoreWebinar presentation: Next-Generation Composites Materials and Processes (July 2020)

CompositesWorld hosted on July 28, 2020, a webinar titled, “Next-Generation Composite Materials and Processes.” If you missed the live webinar, you can watch the recording or download a PDF of the presentation.

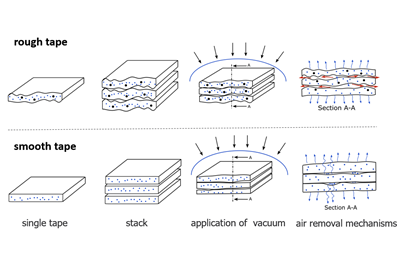

Read MoreTPRC investigates AFP in-situ consolidation alternative

The two-step process involves deposition of thermoplastic prepreg via AFP, followed by vacuum-bag-only (VBO). Research has already been completed in the qualitative stage.

Read MoreElectroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

WatchStrata delivers 100 shipsets of inboard flaps for Airbus A350-900

Strata assumes fabrication and assembly duties for inboard flaps production and plans to incorporate HDF and ATL machines into the process.

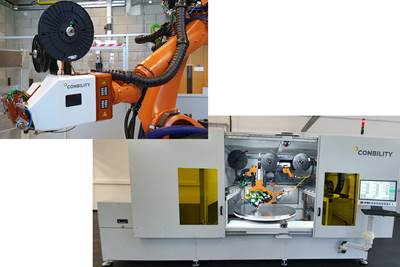

Read MoreConbility: Mass production of composite tape laminates

RWTH Aachen spin-off scales up production for low-cost, in-situ consolidated composites as inserts for lighter, cheaper injection-molded parts.

WatchComposites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

Read MoreZAero project update

The 2019 final review demonstrated integration of an automated CFRP process chain: AFP inline inspection and rework, cure and resin flow sensors, part performance prediction and a decision support tool for line operators.

Read More