Design and Testing

Composites testing as part of a building block approach, Part 1: Coupon-level testing

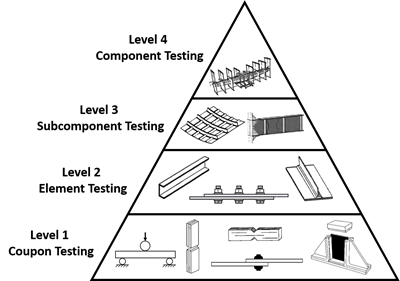

The building block materials testing approach is a step-by-step process that serves as a framework for designing composite structures while also reducing risk and cost.

Read MoreComposite testing challenges, Part 3: Testing systems

Several factors need to be considered for accurate and efficient composites testing, including testing systems that can accommodate required test environments, alignment and offer intuitive software.

Read MoreComposite testing challenges, Part 2: Strain measurement for the mechanical testing of composites

Recent developments in contact and noncontact strain measurement methods offer similar performance with additional benefits for composite material testing.

Read MoreComposite testing challenges, Part 1: Introduction to mechanical testing of composites

A range of standardized mechanical tests for complex composites are available and still under development for materials development, design and quality control requirements.

Read MoreDurability testing of adhesively bonded composites

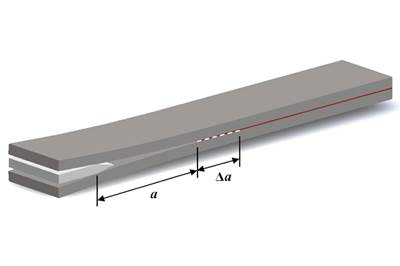

Current test method development shows potential for the composite wedge test, a standardized durability-based test for adhesively bonded composites.

Read MoreFatigue testing of composites

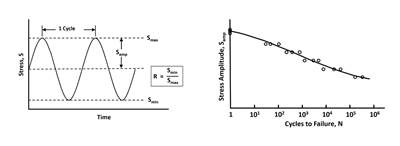

Fatigue testing may be performed at multiple points during the design of a composite structure. A focus on small-specimen level fatigue test methods, however, suggests a need for more testing method standardization.

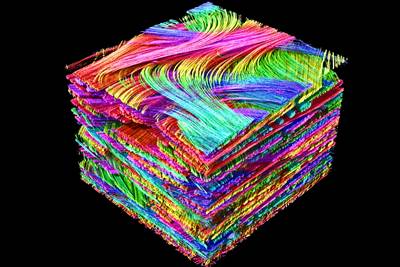

Read MorePart 2: Applying CT scan data analysis and visualization to composites

Advanced CT-scan analyses can offer deep insight into challenges faced when examining novel composites and hybrid material behavior or performing quality and certification testing. Part two of a two-part series.

Read MoreApplying CT scan data analysis and visualization to composites

Imaging and analysis via computed tomography (CT) has potential for certifiable safety and business sustainability and could be key for interior inspections of composite parts. Part 1 of a two-part series.

Read MoreDevelopment of ASTM standards for composites: An insider’s perspective

According to Dan Adams’ inside perspective, two elements determine whether a proposed test method for composite materials becomes an ASTM standard.

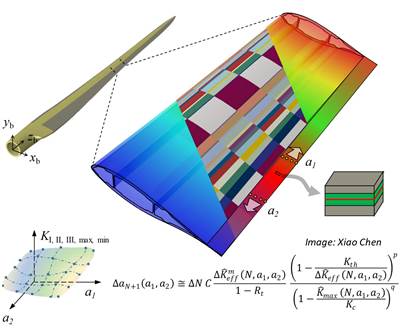

Read MoreFASTIGUE: Empowering digital twins of large-scale composite structures

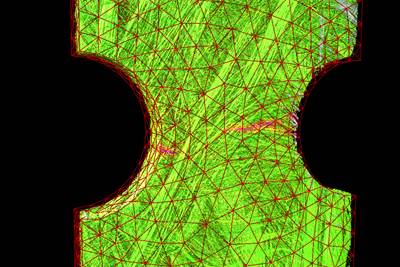

A 3D finite element technique to resolve the fidelity-versus-speed dilemma of performing fatigue analysis for large composite structures.

Read More