Henkel AG & Co. KGaA

Adhesive Technologies - Aerospace

Henkelstrasse 67

Duesseldorf, D-40589 DE

49 211 797 9947

loctite.co.uk/machinery

About Henkel AG & Co. KGaA

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Henkel AG & Co. KGaA Supplies the Following Products

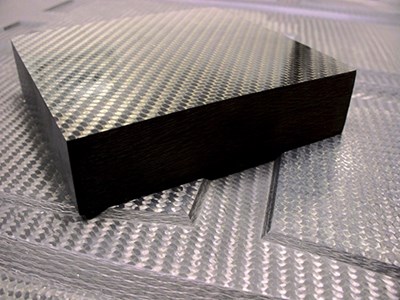

- Epoxy, Film

- Epoxy, Foam

- Epoxy, Paste

- Foam core, epoxy

- Mold release agents, liquid

- Protective

- Syntactic core

Editorial, News, and Products

-

Henkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

Henkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

ALMACO discloses Top of Mind 2021 award finalists

The primary award for the Brazilian composites sector identifies the three most-voted companies in 27 categories. Winners will be announced Dec. 9.

-

Henkel collaborates on study to reduce carbon footprint of aerocomposite parts

Led by Boeing Germany, research group aims to combine traditional manufacturing with digital tools to decrease part weight, optimize production efficiency.

-

Henkel develops REACH-compliant structural adhesive for aircraft interiors

FST-certified Loctite EA 9365FST reinforces and bonds thermoplastic and thermoset substrates and can serve as a matrix resin on fiberglass to strengthen the thin walls of thermoplastic assemblies

-

Henkel, Carbon partnership offers additive manufacturing solutions

The combination of Loctite materials and 3D-printing expertise opens doors for the adoption of high-performance additive manufacturing at scale for industrial customers.

-

Composite Bonding & Repair Benefits and Solutions

Film and paste adhesives, wet peel-ply and potting compounds enable the aviation industry to utilize advanced materials that contribute to lightweighting, more efficient designs, and improved sustainability.

-

Henkel, Fortify partner to enable high-performance applications in 3D printing

The companies are leveraging Fortify’s composite 3D printing technology with Henkel’s resins for injection mold tools and other applications.

-

Henkel to collaborate with Carbon Revolution on composite wheels

Henkel and Carbon Revolution join forces to speed OEM automotive one-piece carbon fiber wheels development.

-

Henkel partnering in SYMPA research project for 3D-printed composites in automotive

Goals include new materials, printing and post-processing technologies for durable fiber reinforcement using stereolithography (SLA) and digital light processing (DLP).

-

Henkel opens European hub for aerospace adhesive solutions

The new production plant in Spain supports lightweighting, fuel efficiency and automation for aerospace applications.

-

Henkel strengthens 3D printing portfolio

Henkel acquires US-based additive manufacturing and industrial inkjet company.

-

Proving viability of dry fabrics, infusion for large aerostructures

Danobat’s ADMP is used to produce a wing demonstrator with non-crimp fabrics.

-

JEC World 2019 briefs

JEC briefs on Bindatex, FILL, Solvay, Henkel, Web Industries, Cobra, PolyOne, GKN Fokker, Thomas Technik + Innovation and Hyosung Advanced Materials.

-

Kaneka Aerospace acheives AS9100D aerospace certification

Kaneka Aerospace’s product portfolio includes high performance resins, prepregs and adhesive materials.

-

Developing next-generation composites talent

The M.C. Gill Composites Center at the University of Southern California has steadily grown to become one of the industry’s educational and R&D stalwarts.

-

Henkel invests in adhesive technology innovation center

The new facility will feature labs, research and testing facilities, office space and conference rooms.

-

Henkel opens Innovation and Interaction Center for 3D Printing

The center will be Henkel’s European regional hub for technology presentations, demonstrations, training and testing, as well as customer service for 3D Printing solutions.

-

Henkel announces novel additive manufacturing materials

Henkel Adhesive Technologies accelerates commercializing tailor-made materials and offers comprehensive services for 3D Printing solutions.

-

Another opportunity to meet, and learn, in Paris

At the JEC World 2017, improvements in materials and processes were present at nearly every stand, with the emphasis on automotive-capable production speeds.

-

Wet and dry peel plies

Thinking of using only peel ply as adhesive bonding surface prep? You should understand all of the issues involved.

-

Structural adhesives, Part II: Aerospace

Tried-and-true legacy epoxies are a must for aerospace composites, but usage is increasing with improved forms.

-

JEC World 2016: Automotive highlights

On the automotive side, Henkel (Düsseldorf, Germany) emphasized on its JEC stand a glass fiber-reinforced composite leaf spring, based on Henkel’s polyurethane matrix resin Loctite MAX 2, used in the chassis of the new Volvo (Gothenberg, Sweden) XC90, a premium crossover SUV; the platform of this vehicle is expected to be applied to other Volvo cars in the coming years.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Materials & Processes: Composites for repair

Composites offer cost-effective means to repair, protect and/or strengthen structures made of steel, concrete or other materials.

-

Aircraft composites repair moves toward maturity

New technologies seek to address the challenges MROs will increasingly face in the age of commercial airliners with composite airframes.

-

A growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

-

3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

-

Ascent Tooling Group ascends via innovation

The world’s largest metal and composite moldmaker has a new name and continues to make a name for itself in closer control of large-part dimensional tolerance.

-

Composites for repair (2015)

Composites now offer a cost-effective means repair and/or strengthen structures made of steel, concrete or other materials.

-

Tooling (2015)

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

The matrix (2015)

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here's a guide to selection.

-

Articulated composite booms extend reach of concrete-pumping arms

A 25% weight reduction vs. legacy steel yields economics that justify upfront cost of carbon fiber.

-

Multi-material rudder: Trailing-edge parts replaced

TCB Composite (West Haven, UT, US) molds replacment parts that keep legacy US Air Force A-10 Thunderbolt II fighter aircraft, affectionately dubbed Warthogs, in the air.

-

JEC Americas 2014 Review

Composites industry exhibitors at this combined show emphasized the textile side of the fiber/resin mix and touted process automation.

-

All-composite ROTORwing prototype UAV

Composites enable construction, and handle unique VTOL loads, of unmanned aerial vehicles’ helicopter-to-airplane conversion.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

The Curiosity Mars rover: Descent stage composites

Apart from the aeroshell that protected the Curiosity rover during its months in space and Mars descent sequence, only a few other parts of the mission’s descent stage were made from composite materials. Here, HPC identifies and describes them.

-

Building a house, with a 3-D printer

A Dutch project is working with Henkel on an effort to 3-D print an entire house to help evaluate material and manufacturing strategies.

-

Meter/mix/dispense machines: Doubling down on control

The latest equipment solutions deliver lower costs, faster cycle times and better part properties.

-

BMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

-

HPC's 20th Anniversary: Thanks to HPC’s charter advertisers

Every trade publication lives and dies by its advertisers, and those who had the gumption to ante up for HPC’s premier issue are listed here and those who are still with us (see page numbers below) are gratefully recognized with the HPC 20th Anniversary Medallion.

-

If not automotive then ... what?

CT columnist and president of Dayton, Ohio-based Quickstep Composites Dale Brosius says it’s not too early for composites industry operatives who are pursuing the automotive holy grail to begin exploration and market development elsewhere.

-

JEC Europe 2013 review

Snow in Paris slowed traffic to the show floor but did nothing to cool the enthusiasm of composites innovators in a broad range of markets.

-

JEC Europe 2013 new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display.

-

Lightning strike protection strategies for composite aircraft

Tried-and-true materials thrive, but new approaches and new forms designed to process faster are entering the marketplace.

-

SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

-

2011 High-Performance Resins Highlights

Attendees reviewed the current state of advanced resin technology and the tests that lay ahead for expanding composites into new applications and markets.

-

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

-

JEC Composites Show 2010 Highlights

Despite the volcanic ash that clouded air travel, an eruption of new technology and new business did much to dispel the clouds of economic recession.

-

Resins for the Hot Zone, Part II: BMIs, CEs, benzoxazines and phthalonitriles

Next-generation aerospace programs demand higher temperatures for structural and hot-section components, fostering advances in thermoset resin chemistry.

-

Composites stabilize space-based telescope

Composite Primary Mirror Backplane Support Structure to hold James Webb Space Telescope’s thermal stability within extremely tight 38-nm dimensional tolerance.

-

JEC COMPOSITES 2008 show review

Composites professionals converged on this annual Parisian gathering in greater numbers than ever before, confident that the market’s global growth will continue.

-

Focus on Design: Composite adaptor board supports medical treatment

Carbon fiber/epoxy the only material choice in this critical X-ray application.

-

JEC COMPOSITES 2007 Product Showcase - 7/1/2007

The annual Paris conclave showcases the global expansion of composites.

-

JEC Composites 2007 Product Showcase

This year’s Parisian exhibition provides key evidence of the composites industry’s unprecedented breadth and technical sophistication.

-

Composite spoilers brake Airbus for landing

New RTM'd carbon composite center hinge fitting withstands 20-ton air load in commercial jet spoiler assembly.

-

Plane Enthusiasts Plan LSA-compliant Composite Aircraft

Aspiring owners build and - plan to market - their own tandem seat, twin-boom pusher.

-

Rapid Fiber Preforming On A Large Scale

A proven alternative to open molding of big parts.

-

Designing for dimensional stability in space

The accuracy of orbiting instruments depends on skillfully designed and manufactured composite components.

-

At the top and still climbing

Trek Bicycles' OCLV manufacturing method shortens cycle times and optimizes compaction in molded carbon fiber-bike frame components.

-

Composites take off ... in some civil helicopters

Slowed by certification requirements, composites nevertheless are finding their way into the fuselages and rotor blades of commercial helicopters.

-

Mold release update

New products from mold release manufacturers emphasize ease of use and application flexibility.

-

Tubular composite core stiffens launch vehicle structure

ChamberCore, an alternative to traditional sandwich laminates, also improves vibro-acoustic damping.

-

Corvette gets leaner with carbon fiber hood

Advances in materials and processing yield high-volume, low-mass hood for GM flagship.

-

Vinyl ester composite parts in boat stern drive resist corrosion and damage

Volvo Penta's Ocean Series brings vinyl ester composites to the powertrain end of the boat.

-

New film and paste adhesives for specialized applications

Customer performance demands drive thriving film and paste technology development.

-

SAMPE Wrap Up And Product Showcase

Exhibitions on both sides of the Atlantic spur optimism and spotlight innovative technology.