Wyoming Test Fixtures, Inc.

2960 E Millcreek Canyon Rd.

Salt Lake City, UT 84109 US

801-484-5055

wtf@wyomingtestfixtures.com

wyomingtestfixtures.com

About Wyoming Test Fixtures, Inc.

Design and fabrication of all types of mechanical test fixtures for testing composites, plastics, ceramics, metals, adhesives, fasteners and sandwich panels.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Wyoming Test Fixtures, Inc. Supplies the Following Products

- Ceramic matrix composites

- Compression-after-impact testers

- Consulting, materials

- Fatigue-testing equipment

- Flexural testers

- Impact-testing equipment

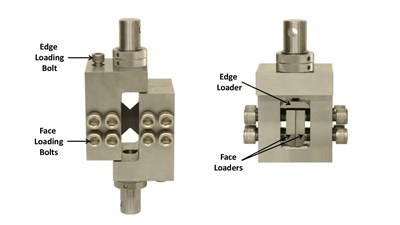

- Mechanical test fixtures

- Modulus testers

- Other testing equipment

- Tack monitoring equipment

- Tensile testers

- Testing, materials

- Testing, product

Editorial, News, and Products

-

Remembering Don Adams

When one thinks of composites test methods, one thinks of Don Adams. Don passed away at the end of 2022. We remember him here.

-

Longtime composites industry veteran Donald F. Adams passes

With great sadness CW announces the passing of Donald (Don) Adams, professor of mechanical engineering at the University of Wyoming and president of Wyoming Test Fixtures.

-

Shear testing of high-shear strength composite laminates

CW columnist Dan Adams compares three V-notched shear test configurations used to measure the shear stiffness and shear strength of composite materials.

-

Gripping composite test specimens: Options and guidance

Orthotropic behavior of composites test specimens makes load introduction uniquely challenging.

-

Bearing testing of composites

CW columnist Dr. Dan Adams (Wyoming Test Fixtures, Salt Lake City, UT, US) reviews the available options for testing the bearing strength of mechanically fastened composite joints.

-

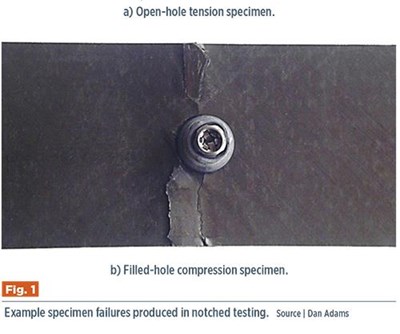

Notched testing of composites

Open-hole test methods were developed in the early 1980s to compare toughness increases in new composite materials.

-

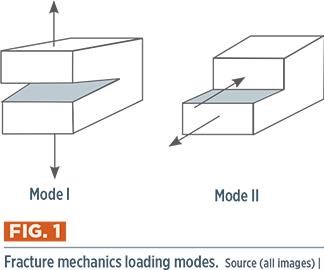

Fracture mechanics testing of composites

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah, and vice president of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US), addresses ways to acquire mechanical test data and then calculate the values for the composite material property of fracture toughness.

-

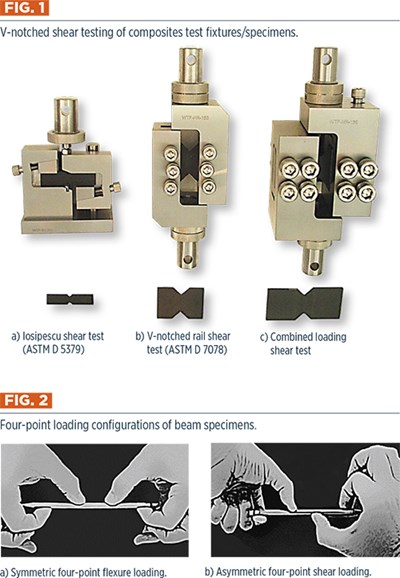

V-notched shear testing of composites

Dr. Daniel O. Adams, professor of mechanical engineering and director, for 18 years, of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US), reviews the most popular V-notched shear test methods for composite materials.

-

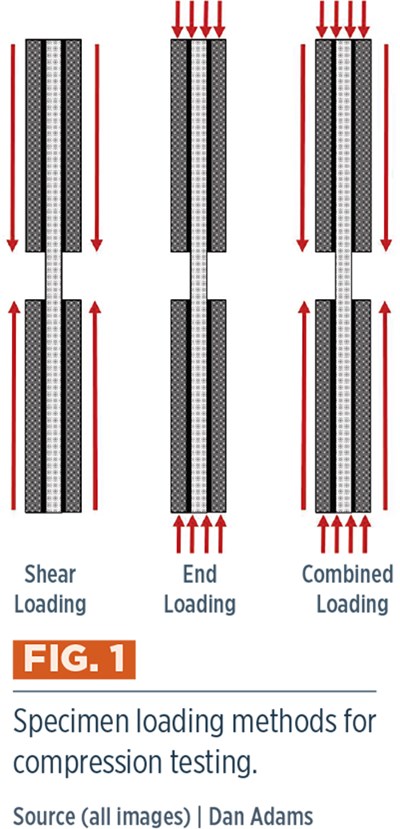

Optimum unidirectional compression testing of composites

Dr. Daniel O. Adams, a professor of mechanical engineering, the director of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) discusses the complex relationship between composite tensile and compressive properties, why that makes it necessary to perform both tension and compression testing, and how best to perform the latter.

-

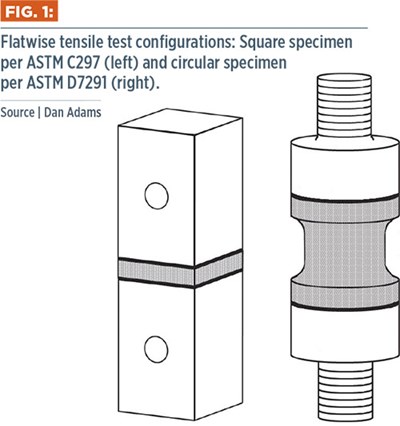

Methods for interlaminar tensile testing of composites: A comparative evaluation

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) compares and contrasts the direct and indirect loading methods for interlaminar tensile testing of composites.

-

Tensile testing composites: Simple concept, difficult in practice

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah, and the vice president of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US), takes over for his father, Dr. Donald F. Adams, as the anchor writer in CompositesWorld magazine's revamped CW Design and Testing column. First subject? The challenges of tensile testing unidirectional composites.

-

The Picture Frame Shear Test method

Dr. Donald F. Adams (Wyoming Test Fixtures, Salt Lake City, Utah) reviews the history of the Picture Frame Shear Test method.

-

The evolution of the modified D 695 compression test method

HPC's Testing Tech columnist Dr. Donald F. Adams,the president of Wyoming Test Fixtures Inc. (Salt Lake City, Utah), looks at the long metals-to-plastics-to-composites history of this well-used and much modified compression test method.

-

Compact tension fracture toughness testing

Dr. Donald A. Adams, president of Wyoming Test Fixtures Inc. (Salt Lake City, Utah) discusses compact tension fracture toughness testing.

-

Reversed loading flexural fatigue

Dr. Donald F. Adams, owner and president of Wyoming Test Fixtures (Salt Lake City, Utah) discusses reverse loading flexural fatigue testing and fixture design.

-

Buckling of composite material compression specimens

Dr. Donald F. Adams (Wyoming Test Fixtures, Salt Lake City, Utah) rehearses the causes of, and solutions for, problems with buckling in composite compression specimens.

-

The Short Beam Shear test method for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) suggests larger support and loading cylinders for the Short Beam Shear test method.

-

HPC's 20th Anniversary: Thanks to HPC’s charter advertisers

Every trade publication lives and dies by its advertisers, and those who had the gumption to ante up for HPC’s premier issue are listed here and those who are still with us (see page numbers below) are gratefully recognized with the HPC 20th Anniversary Medallion.

-

The Double-Notch Shear test specimen for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) recommends best practices for double-notch shear test specimens.

-

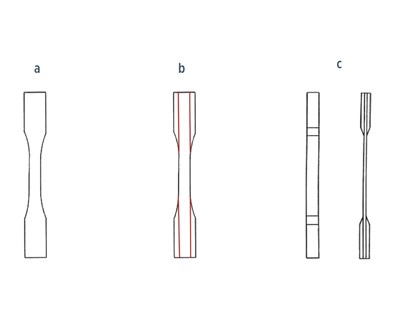

Thickness-tapered unidirectional composite specimens

Sometimes a testing concept is known for a long time but is never developed into an established test method.

-

Flexural test method standards for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) proposes a common-sense standard method for flexural testing of composite materials.

-

Flexural testing of composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) takes look at flexural testing and promises recommendations, next time, for a unified standard.

-

Composites testing: The continuing standards dilemma

Dr. Donald F. Adams revisits the topic of global test standardization, suggesting a simple but unlikely fix to the lack of harmonization.

-

Virtual testing of composites: Beyond make & break

Software-based micromechanical modeling and analysis methods promise faster and more cost-effective aircraft development and testing programs.

-

Fracture mechanics test methods for sandwich composites

HPC's testing guru, Dr. Donald F. Adams (Wyoming Test Fixtures, Salt Lake City, Utah), surveys the available fracture mechanics test methods for sandwich panels.

-

Testing the crashworthiness of composite structures

Dr. Donald F. Adams examines automobile crashworthiness, noting popular crashworthiness test methods for composites, and points out the lack of, and current progress toward, standardized testing for composite crash structures.

-

Composites testing at elevated temperature and moisture content

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) notes the renewed interest in testing composites under hygrothermal conditions.

-

Impact testing of composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) discusses the methods for impact testing of composites.

-

Testing the damage tolerance of composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures, Salt Lake City, Utah) looks at standards and also-rans in the area of testing for damage tolerance.

-

Material deformation and recovery test methods

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) reviews ways and means to quantify composite material deformation and recovery.

-

Comparison of shear-loaded compression test fixtures

Dr. Donald F. Adams compares the three basic types of shear-loaded compression test fixtures.

-

Laminate bearing/bypass interaction test methods

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) reviews laminate bearing/bypass interaction test methods.

-

The Combined Loading Compression (CLC) test method

Dr. Don Adams discusses the relative merits of the ASTM-adopted combined loading compression (CLC) test method.

-

Tabbing composite test specimens: The how

The when and why of tabbing composite test specimens were the subjects of my previous column (see “Tabbng composite test specimens: When and why," under "Editor's Picks," at right), which included a discussion of tabbing materials, tab thickness and taper angle, and adhesive selection.

-

Tabbing composite test specimens: When and why

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses when and why test specimens must be protected by tabs.

-

Fiber-matrix interfacial bond test methods

Dr. Don Adams describes six single-fiber methods for testing fiber-matrix interfacial bond strength.

-

Transverse flexure testing

Dr. Donald Adams examines test methods for determining the transverse tensile strength of a composite formed from unidirectional plies.

-

The short beam shear test

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses short beam shear testing methodology.

-

Fastener shear test methods

Dr. Donald Adams (Wyoming Test Fixtures, Salt Lake City, Utah) appraises existing methods for testing the performance of fasteners loaded in transverse shear.

-

Guide for Testing Polymer Matrix Composite Materials

Dr. Donald Adams offers insight into ASTM D 4762, a compendium of knowledge about standards relevant to testing polymer composites.

-

Block shear strength of adhesive bonds

Dr. Don Adams describes two methods (ASTM D 905 and ASTM D 4501) for loading adhesive bonds in direct shear while minimizing undesirable peel and through-thickness tensile stresses.

-

Additional grip types for tensile test specimens

Dr. Don Adams follows up a previous discussion of wedge grips for testing tensile specimens with a sampling of other grip types.

-

Shear test methods: Iosipescu vs. V-Notched Rail

Dr. Don Adams asks and suggests a likely answer to the question Which shear test method is best?

-

A comparison of shear test methods

Dr. Don Adams compares the shear test methods that are currently available to the composite industry.

-

V-Notch Rail Shear test (ASTM D 7078-05)

Dr. Don Adams introduces HPC readers to the The V-Notched Rail shear test method, approved as ASTM Standard D 7078-05 by ASTM Committee D-30 in March of 2005.

-

Direct measurement of laminate through-thickness tensile strength

Although there are indirect methods for determining the through-thickness tensile strength of a solid laminate direct loading can be achieved, using ASTM test methods.

-

Mixed-mode fracture toughness of composites

During the 1970s, fracture toughness testing of composite materials developed a very poor reputation, primarily due to failed attempts to directly adopt metals theory and corresponding test methods. However, the basic principles of fracture mechanics remained valid.

-

Compression platens and subpresses

Dr. Don Adams discusses the use of compression platens (fixed and spherical seat) and subpresses to ensure reliable test frame operation.

-

Neat resin specimen fabrication aids

To obtain quality experimental data, one must have access to quality test specimens.

-

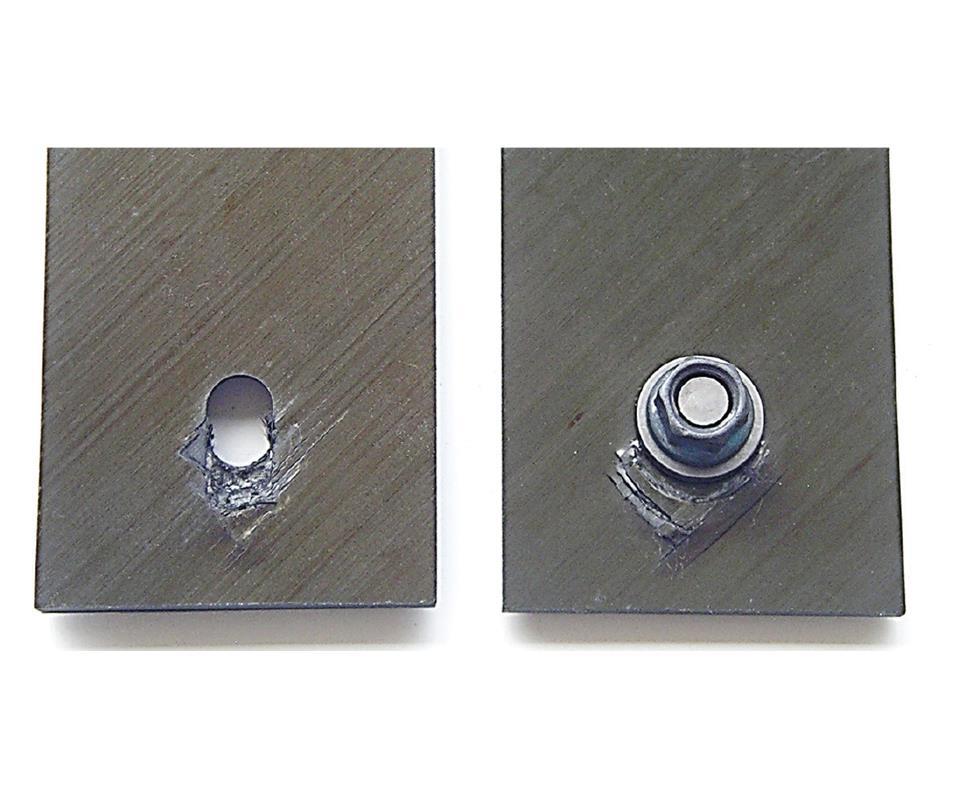

Fastener pull-through strength test method

Mechanical fasteners have been used to join wood and metal plates for hundreds of years.

-

Flexural testing of fiber-reinforced ceramics

Because of their brittle nature, ceramics, fiber-reinforced or unreinforced, are difficult to test in pure tension, compression and shear, primarily due to difficulties in gripping and uniformly loading the brittle specimen.

-

Testing Tech: Multiple-fastener, single-shear laminate bearing strength testing

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) follows up his HPC January 2008 discussion of double-shear testing of a single fastener while advice about testing multiple fasteners under single-shear loading conditions.

-

Single-fastener, double-shear laminate bearing strength by tensile testing

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses a laminate bearing strength test using double-shear loading of a single fastener.

-

The modified D695 compression test method

Dr. Don Adams discusses the evolution of the ASTM D 695 compression test method, the predecessor of the D 6641 method now in wide use.

-

Sandwich panel flexure testing

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) comments on the composite materials testing community's move toward the use of the terms "long beam flexure" and "short beam flexure" when addressing sandwich panel testing.

-

Back-out factors

Dr. Adam's follows up a previous column, in which he discussed the advantages of testing a cross-ply laminate and then "backing out" the unidirectional composite strength, with an expanded examination of back-out factors that can be applied to other types of laminates.

-

Testing cross-ply vs. unidirectional composites

Dr. Don Adams follows up his previous column on tensile testing with a discussion of such testing when confronted by two difficult-to-test laminate configurations.

-

Unidirectional composite axial tensile specimens

Dr. Don Adams explains why the design of tensile test coupons is more art than science, and explains the implications of that art for testing accuracy.

-

Flexure test methods

The three fundamental mechanical property characterization tests of materials are tension, compression and shear. Note that flexure is not included. This article addresses some of the reasons why. When a beam resting on supports near its ends is loaded, the supported side is in tension and the opposite side is in

-

Current compression test methods

Dr. Don Adams discusses the test methods and fixtures currently available to test the compressive strength of composites.